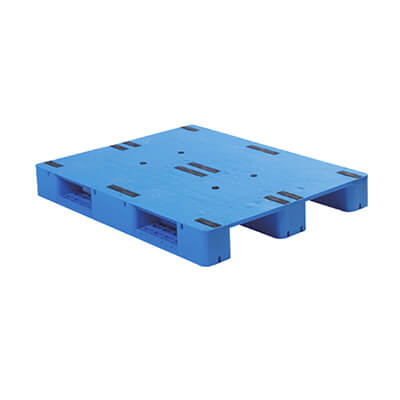

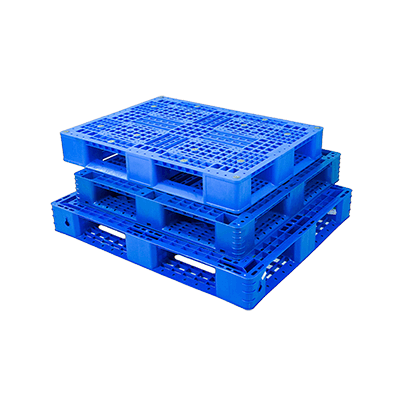

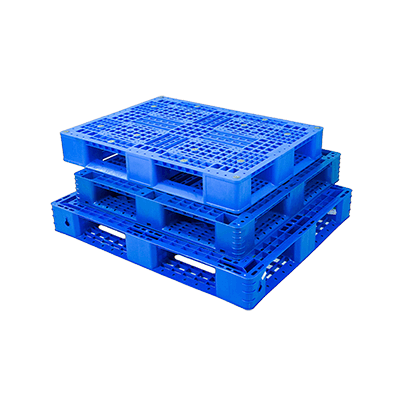

Stackable Plastic Pallets

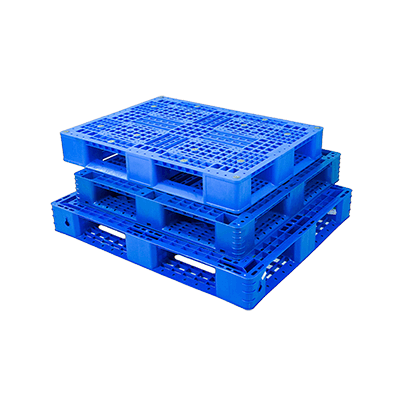

Maximize your storage space with our stackable plastic pallets. These pallets are designed to securely stack on top of each other, providing stable and organized storage for your products. Their durability ensures long-lasting performance in demanding environments.

Welcome to our comprehensive guide to stackable plastic pallets, the ultimate resource for all your stackable pallet needs. As a leading manufacturer and exporter of plastic pallets, we are committed to providing you with the most reliable and informative information to help you make informed decisions when purchasing stackable plastic pallets.

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the download link immediately.

Introduction to Stackable Plastic Pallets

Stackable plastic pallets are designed with specific features that make them easy to identify and differentiate from other types of pallets.

What are Stackable Plastic Pallets?

Stackable plastic pallets are specially designed to allow for easy vertical stacking, even when fully loaded with goods. Their sturdy construction ensures stability and durability, making them ideal for heavy loads and challenging environments.

Key Features and Characteristics:

Stackable plastic pallets offer efficient vertical stacking, sturdy construction, and uniform size for optimal space utilization. Their smooth surfaces enhance hygiene, while their lightweight yet durable design reduces transportation costs. Compatible with various handling equipment, these pallets are hygienic, weather-resistant, and ideal for industries like food and pharmaceuticals.

Nestable vs. Stackable Pallets

While nestable plastic pallets are excellent for space-saving and efficient return logistics, stackable pallets are designed for easy vertical stacking when fully loaded. The choice between nestable and stackable pallets depends on your specific storage and handling needs. Stackable pallets are ideal for maximizing storage space, whereas nestable pallets excel in optimizing empty pallet storage and return transportation

Mtcplast Stackable Plastic Pallets Series

Want to purchase plastic pallets onboard? This ultimate solution guide would help you everything about buying products.

Advantages of Stackable Plastic Pallets

Space-saving and Versatile

Vertical Stacking

Stackable plastic pallets are designed to securely stack on top of one another, allowing for efficient use of storage space. This feature is particularly beneficial in warehouses, distribution centers, and transportation, where maximizing vertical space is crucial.

Hygienic Properties

Stackable plastic pallets are easy to clean and sanitize, making them suitable for industries that require strict hygiene standards, such as food and pharmaceuticals. They are resistant to bacteria, molds, and mildew, ensuring product integrity and safety.

Sturdy Construction

Stackable plastic pallets are built to withstand the weight of heavy loads without buckling or deforming. They feature reinforced corners and robust construction, ensuring they can endure rigorous material handling operations.

Uniform Size and Shape

Stackable pallets are designed to have consistent dimensions and configurations. This uniformity simplifies stacking and ensures a stable foundation for your products during storage and transportation.

Compatibility with Automated Systems

Many stackable plastic pallets are designed to be compatible with automated systems, such as conveyor belts or robotic handling equipment. Their uniform size and shape allow for smooth integration into automated workflows, enhancing operational efficiency.

Rounded corner design to prevent collisions.

The pallet with rounded corner legs is designed to provide cushioning upon impact, preventing damage during falls, and offering collision protection during forklift operations, thereby extending the pallet’s lifespan.

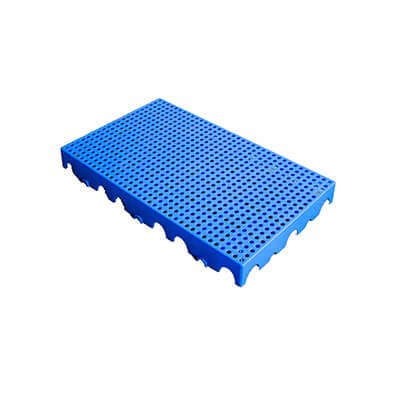

Grid perforation design.

The surface’s perforated design allows for water and moisture resistance, ensuring proper ventilation and preventing water accumulation at the bottom of the goods.

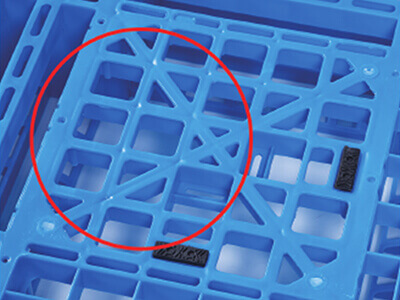

Pallet surface with anti-slip mat design.

The anti-slip mat design on the pallet surface provides excellent friction between the pallet and the goods, preventing the goods from sliding off the pallet.

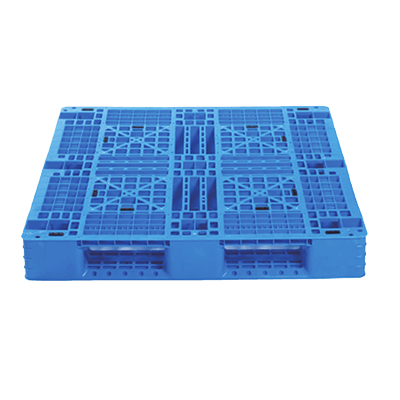

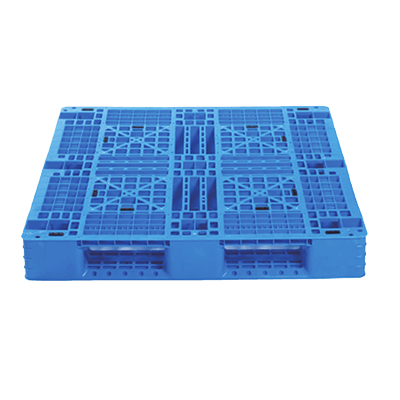

Fulll perimeter base pallet

Stable structure, not easily damaged, convenient for secondary stacking with goods, and saves storage space.

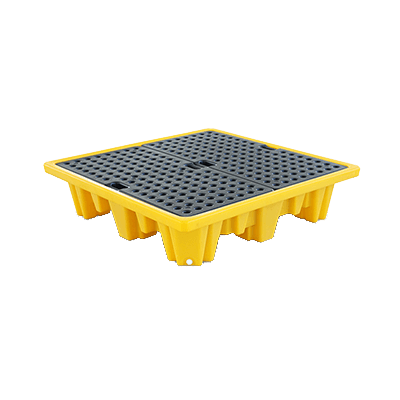

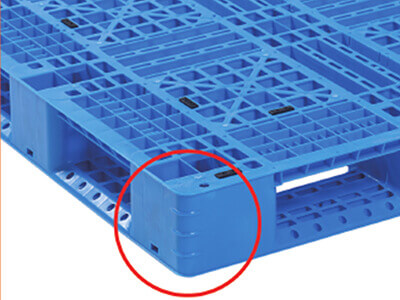

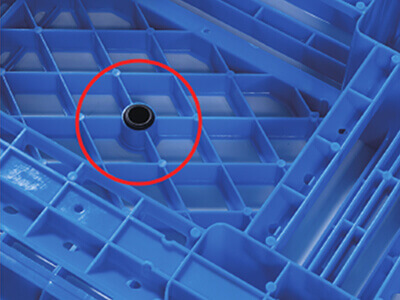

Bottom anti-slip pad design.

The pallet’s bottom is equipped with anti-slip blocks for cargo, and the fork holes have anti-slip blocks for forklifts, enhancing the anti-slip performance and ensuring safer usage.

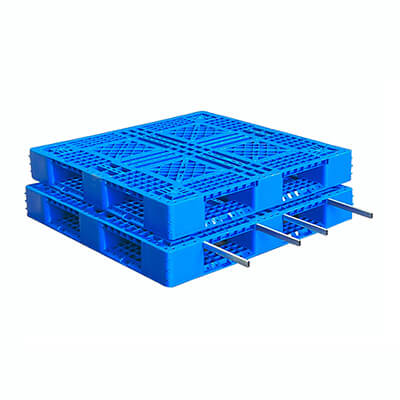

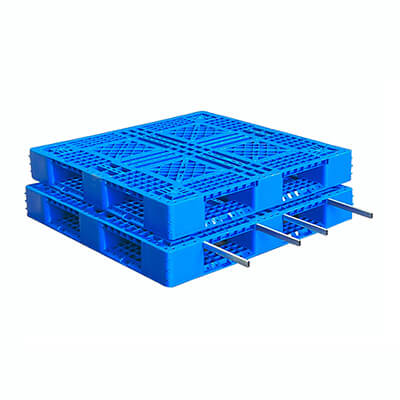

Steel pipes available

Stackable plastic pallets feature a design that allows for the addition of steel bars, catering to various load-bearing requirements.

Stackable Plastic Pallets Application

Stackable plastic pallets have widespread applications across various industries. Some common industries that benefit from using stackable plastic pallets include:

How to Identifying Stackable Plastic Pallets

Identifying stackable plastic pallets involves examining their distinctive features and characteristics. Here are some key aspects to consider when identifying stackable plastic pallets:

Construction and Material

Stackable plastic pallets are typically made from durable plastics such as HDPE or PP. They have a solid construction and are molded using injection molding or structural foam molding processes. Look for the plastic material code (e.g., HDPE or PP) on the pallet or check the product specifications for details.

Surface Texture and Design

Stackable plastic pallets often have anti-slip surfaces to prevent products from shifting during transport. Check for textured or ribbed surfaces that provide traction and stability. Additionally, look for features like raised edges or containment lips that help keep goods in place on the pallet.

Load Capacity

Stackable plastic pallets are designed to handle different load capacities, ranging from light-duty to heavy-duty applications. Look for load capacity specifications, usually measured in pounds or kilograms, to ensure the pallet can support your intended load.

Stacking Features

The key distinguishing feature of stackable plastic pallets is their ability to securely stack on top of each other. Examine the design elements that enable proper stacking, such as interlocking corners, stacking rims, or reinforced edges. Look for indicators that show the pallets can be safely stacked without toppling or shifting.

Why Choose Mtcplast.com?

We are a company that values customers’ satisfaction. We always aim at producing and delivering quality plastic pallets that meet all your needs.

Extensive Industry Experience:

With years of expertise in the material handling industry, we have a deep understanding of your business needs. Our experience allows us to provide tailored solutions that enhance your logistics and warehouse operations.

High-Quality Products

We take pride in offering top-notch stackable plastic pallets made from premium materials. Our products undergo rigorous quality checks to ensure they meet the highest standards and deliver exceptional performance.

Customization Options

We understand that every business has unique requirements. That’s why we offer a wide range of customization options for stackable plastic pallets, allowing you to choose the perfect size, weight capacity, and color that aligns with your specific needs.

Expert Guidance

Our team of material handling specialists is ready to provide expert guidance throughout your decision-making process. We’ll assist you in selecting the ideal stackable plastic pallets that best suit your industry and application.

Reliability and Durability

When you choose us, you gain access to stackable plastic pallets known for their reliability and durability. Our products are built to withstand heavy loads, ensuring long-lasting performance in demanding environments.

Excellent Customer Service

At every step of your journey with us, you’ll experience excellent customer service. From inquiries to after-sales support, our dedicated team is here to provide prompt and reliable assistance.

Choose us as your trusted partner for stackable plastic pallets and experience the difference in material handling efficiency and cost-effectiveness. Contact us today to get started on optimizing your logistics and warehouse operations.

Estimate Cost of Stackable Plastic Pallets

The cost of stackable plastic pallets is subject to variation due to factors like size, design, load capacity, customization, and order quantity. For an accurate estimate, reach out to our sales team or request a quote with your specific pallet details. We’ll gladly provide a competitive pricing proposal tailored to your requirements. Below is a cost outline for your reference

Sample Product Fee

Pay a minimal amount in case you need a sample plastic pallet. Well, this money is for a single sample, if it is the one that you need. With several samples, you’ll pay a bit more.

30% T/T Fee

You have the option to either make the full payment or pay a 30% deposit for wholesale purchases.

70% Final Fee

Complete your payment within a certain period and receive the products you ordered for.

Shipping Fee

This is the amount of money that you will pay for the transportation of your products from the factory to your doorstep. MTCPLAST offers you the convenience of any kind.

Estimated Manufacturing and Shipping Times

The estimated manufacturing and shipping times of stackable plastic pallets can vary based on several factors, including the order quantity, customization requirements, and current production capacity. Here’s a general overview of the process

Manufacturing Time

The manufacturing time for nestable plastic pallets typically depends on the production volume and complexity of the order. Smaller orders with standard specifications may have a quicker turnaround time, while larger or customized orders may require additional production time. It is best to consult with our sales team to get an accurate estimate based on your specific requirements. Generally it takes 15-25 working days to finish your order if witin 3000pcs

Customs declearance and loading

Once your order is finished and we get the balance of the order, we’ll load them onto vans and wait for them to be decleared by Customs.

International Delivery

After decleared, your plastic pallets will then be shipped to you through international waters. You’ll receive an alert on your mobile device when your order arrives.

Steps to work with us

Working with us is a straightforward process designed to ensure a smooth experience for our customers. Here are the steps to work with us:

Contact and Consultation

Reach out to us through our website, email, or phone to initiate the conversation. Our responsive team will be available to answer your inquiries, discuss your requirements, and provide any necessary guidance or clarification. We will gather essential details about your needs, such as pallet specifications, quantities, customization requirements, and desired timelines.

Quotation

Based on the information provided, we will prepare a comprehensive quotation tailored to your specific requirements. The quotation will include details such as pricing, delivery timelines, customization options, and any additional services or support you may require. We strive to offer competitive pricing and transparent information to assist you in making an informed decision.

Order Confirmation

Once you review the quotation and are ready to proceed, confirm your order by accepting the quotation and making the necessary arrangements, such as providing payment details and signing any required documentation. Our team will guide you through this process and address any questions or concerns you may have.

Manufacturing and Customization

Our skilled manufacturing team will begin the production process according to the agreed-upon specifications. If you have requested any customization, such as size variations, color choices, or branding options, our experts will ensure that your pallets are tailored to your specific needs. Throughout the manufacturing process, we maintain stringent quality control measures to ensure the highest standards are met.

Quality Assurance and Inspection

Before shipment, our quality assurance team will thoroughly inspect the finished plastic pallets to ensure they meet our rigorous quality standards. This inspection process includes checking for any defects, verifying dimensions and load capacities, and ensuring compliance with any requested customization.

Shipping and Delivery

Once the quality inspection is completed, we will arrange the shipping and delivery of your plastic pallets. We work with trusted logistics partners to ensure prompt and reliable delivery to your desired location. Shipping times may vary depending on the destination and shipping method chosen. We will provide you with tracking information so you can monitor the progress of your shipment.

After-Sales Support

Our commitment to your satisfaction extends beyond the delivery of your plastic pallets. We offer comprehensive after-sales support to address any post-delivery questions, concerns, or issues that may arise. Our dedicated customer support team is available to assist you with any further inquiries, technical guidance, or ongoing collaboration.

Things you need to know

Frequently Asked Questions (FAQs) – Your Stackable Plastic Pallets Queries Answered

Can stackable plastic pallets be used outdoors?

Yes, stackable plastic pallets are designed to withstand outdoor conditions. They are resistant to moisture, UV rays, and temperature variations, making them suitable for both indoor and outdoor applications.

How much weight can stackable plastic pallets support?

The load capacity of stackable plastic pallets varies depending on the size, design, and specific model. Our stackable plastic pallets can typically handle loads ranging from 1,000 to 5,000 pounds, ensuring stability and reliability for various industry requirements.

Are stackable plastic pallets compatible with forklifts and pallet jacks?

Yes, stackable plastic pallets are compatible with standard forklifts and pallet jacks. They are designed with openings to accommodate forklift tines or pallet jack forks, ensuring easy and secure handling.

Are stackable plastic pallets easy to clean and sanitize?

Absolutely. Stackable plastic pallets have a smooth surface that is easy to clean and sanitize. They can be washed, rinsed, or pressure-washed, making them ideal for industries with strict hygiene requirements, such as food and pharmaceuticals.

Do stackable plastic pallets comply with international shipping regulations?

Yes, our stackable plastic pallets comply with international shipping regulations. They meet the necessary requirements for safe and secure transportation, making them suitable for both domestic and international shipments.

Can stackable plastic pallets be customized with our company logo or branding?

Absolutely. We offer customization options, including adding your company logo, branding, or labeling systems to the stackable plastic pallets. This enables easy identification and helps promote your brand image.

How long do stackable plastic pallets last?

Stackable plastic pallets have a long lifespan compared to traditional wooden pallets. With proper use and maintenance, they can last for years, reducing the need for frequent replacements and minimizing overall pallet costs. requirements.

Are stackable plastic pallets compatible with automated systems?

Yes, many stackable plastic pallets are designed to be compatible with automated systems, such as conveyor belts or robotic handling equipment. Their uniform size and shape allow for seamless integration into automated workflows, optimizing efficiency and productivity.

Can stackable plastic pallets be used in cold storage or refrigerated environments?

Certainly. Stackable plastic pallets are well-suited for cold storage and refrigerated environments. They are resistant to low temperatures and do not absorb moisture, ensuring their structural integrity and preventing damage in such conditions.

Ready to Elevate Your Material Handling?

Unlock the benefits of MTCPlast’s stackable plastic pallets:

- Space Maximization: Double down on storage efficiency by easily stacking these pallets, saving you valuable warehouse space.

- Enhanced Durability: Trust in our pallets' robust design for long-lasting performance, reducing replacement costs.

- Cost Savings: Streamline shipping with stackable pallets to lower freight expenses.

- Customization: Tailor your pallets to your specific requirements for a seamless fit into your operations.

- Environmentally Responsible: Choose eco-friendly solutions that align with your sustainability goals.

At MTCPlast, your success is our priority. Join countless satisfied customers who have optimized their material handling. Contact us to experience the efficiency and cost-savings stackable plastic pallets can offer.

Make the smart choice for your business today!