Introduction

In today’s world of logistics and trade, plastic crates have become indispensable logistics solutions. They offer various types of plastic crates designed for different purposes. If you are seeking information about the different types of plastic crates, you’ve come to the right place. This article will explore various types of plastic crates, their features, and their applications. Whether you are in agriculture, manufacturing, retail, or other industries, we believe this article will provide you with valuable insights to help you choose the right plastic crates for your needs.

Now, let’s take a closer look at what you can expect in this article. We’ll delve into several key categories of plastic crates, each with its unique features and practical applications. Here’s a brief outline of what we’ll cover:

Now, let’s take a closer look at what you can expect in this article. We’ll delve into several key categories of plastic crates, each with its unique features and practical applications. Here’s a brief outline of what we’ll cover:

Table of Contents

Ventilated Vegetable Crates: Exploring the Design and Advantages for Fresh Produce Storage and Transport

Ventilated vegetable crates are a vital component in the agricultural and food industry, providing an efficient and hygienic solution for the storage and transportation of fresh produce. Here’s a closer look at the design and advantages of these crates:

Design

Ventilated vegetable crates are typically designed with an open, perforated structure that allows air circulation. These small perforations or openings are strategically placed on the sides and bottom of the crates. The design promotes proper ventilation, reducing the risk of moisture buildup and ensuring that the produce remains fresh and free from mold or rot.

Advantages

Freshness Preservation: The key advantage of these crates is their ability to maintain the freshness of fruits and vegetables. The ventilation system helps regulate temperature and humidity, preventing the produce from deteriorating quickly.

Hygiene: Ventilated crates are easy to clean and sanitize, which is crucial when handling food products. Their design minimizes the accumulation of dirt and contaminants.

Visibility: The perforations offer excellent visibility of the contents, which is essential for quality control and inventory management.

Stackability: Ventilated crates are stackable, saving valuable storage space in warehouses and during transportation.

Eco-Friendly: These crates are often made from recyclable materials, contributing to environmentally responsible practices

Applications

Ventilated vegetable crates find applications in various sectors, including:

Farming: Used in the harvesting and packing of fresh fruits and vegetables in the field.

Wholesale Markets: Ideal for transporting produce from farms to wholesale markets.

Supermarkets: Retailers use these crates for storing and displaying fresh produce.

Food Export: Crucial in the export of fruits and vegetables, ensuring they reach distant markets in optimal condition.

In summary, ventilated vegetable crates are an essential tool in the preservation of fresh produce. Their design allows for proper airflow, maintaining the quality and extending the shelf life of fruits and vegetables. Whether you’re a farmer, distributor, or retailer, these crates are a reliable choice for ensuring the quality of your fresh produce throughout the supply chain.

Closed Plastic Crates: Discovering the Benefits for Manufacturing and Spare Parts Storage

Closed plastic crates, with their sealed design, offer a range of advantages that make them indispensable in specific industries. Let’s examine these benefits in detail:

Benefits

Protection from Contaminants: Closed plastic crates provide an effective barrier against dust, dirt, and other contaminants. This protection is especially crucial in manufacturing environments where sensitive components or spare parts must be stored in pristine condition.

Security: The sealed nature of these crates enhances security by preventing unauthorized access to the contents. This is vital when storing valuable or sensitive materials.

Durability: Closed plastic crates are typically constructed from robust materials, making them long-lasting and resistant to wear and tear. They can withstand the rigors of industrial use.

Stacking Capability: Similar to other plastic crates, closed crates can be stacked efficiently. This saves storage space and facilitates organized inventory management.

Moisture Resistance: The sealed design helps to keep moisture out, ensuring that sensitive items such as electrical components or machinery parts remain dry and undamaged.

Customization: These crates can often be customized to fit the specific needs of the industry. This includes the addition of compartments, dividers, or labels to further organize the contents.

Applications

Manufacturing: Closed plastic crates are an excellent choice for storing sensitive manufacturing materials, including electronics, precision instruments, and mechanical components.

Spare Parts Storage: In industries where spare parts are essential for maintenance and repairs, these crates keep critical components in optimal condition until needed.

Aerospace and Automotive: Both of these industries rely heavily on sealed crates to protect delicate and costly parts, ensuring they are in perfect condition when required for assembly.

High-Value Goods: Any industry dealing with high-value goods, whether it’s technology, medical equipment, or specialized machinery, can benefit from the security and protection offered by these crates.

Closed plastic crates are the go-to solution when safeguarding the integrity of materials and components is paramount. Their durability, security, and versatility make them a valuable asset in manufacturing and spare parts storage, allowing businesses to maintain their operational efficiency and product quality.

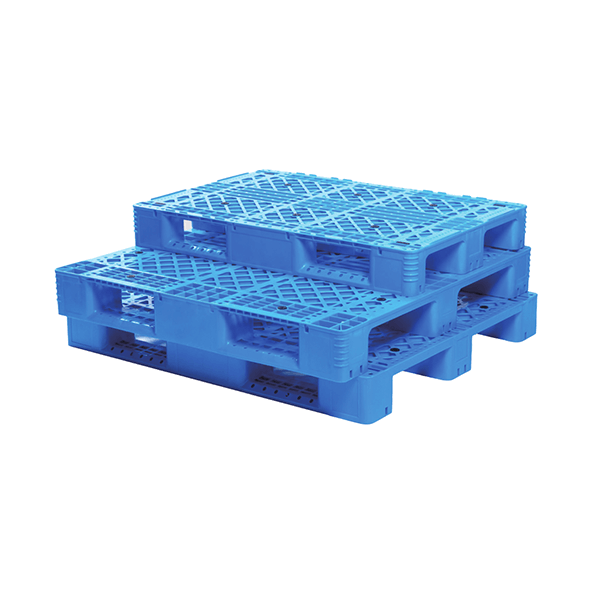

Industrial Plastic Trays: Understanding the Strength and Stackability for Logistics and Warehousing

Industrial plastic trays are the unsung heroes of logistics and warehousing. They offer a multitude of benefits, particularly in terms of their durability and stackability. Here’s a closer look at these trays and their pivotal role:

Strength and Durability

Heavy-Duty Design: Industrial plastic trays are engineered for heavy-duty use. They are constructed from sturdy materials, such as high-density polyethylene (HDPE), which can withstand substantial weight and impact without breaking or deforming.

Resistance to Corrosion: These trays are resistant to moisture, chemicals, and most corrosive substances, making them ideal for industries where materials may come into contact with hazardous or corrosive agents.

Impact Resistance: Industrial plastic trays can endure rough handling, accidental drops, and impacts, ensuring that the items they carry remain undamaged.

Stackability

Space Optimization: One of the key advantages of industrial plastic trays is their stackability. When not in use, they can be nested or stacked to save valuable floor space in warehouses and during transportation.

Enhanced Organization: Stacking trays neatly organizes inventory, allowing for quick and easy access to goods when needed. This improves efficiency in logistics and warehousing operations.

Reduced Risk of Damage: Stacking trays securely in a uniform manner reduces the risk of damage to the items being transported. This is especially critical for fragile or delicate products.

Applications

Material Handling: Industrial plastic trays are used to transport raw materials, semi-finished goods, and finished products within manufacturing facilities.

Warehousing: In warehouses, these trays are invaluable for storing and organizing products. Their stackability ensures efficient use of space.

Logistics and Distribution: Industrial plastic trays play a crucial role in the transportation of goods. They can be used in trucks, shipping containers, and pallets for safe and efficient transport.

Food and Beverage Industry: These trays are used to transport packaged foods, bottles, and other products, maintaining the integrity of the items during transit.

Pharmaceutical and Healthcare: For pharmaceuticals and medical supplies, the trays ensure a clean and organized way of handling and transporting sensitive materials.

Industrial plastic trays are a workhorse of the logistics and warehousing world. Their robust design, resistance to damage, and stackability make them a cost-effective and efficient solution for businesses, ensuring that goods are transported and stored safely and systematically.

Security Crates: Ensuring the Safety of High-Value Goods in Retail and Logistics

Security crates play a pivotal role in safeguarding high-value goods during transportation, storage, and retail operations. Let’s delve into the details of these specially designed crates and their significance:

Design and Features

Asset Protection: Security crates are paramount for the protection of high-value assets, including electronics, jewelry, pharmaceuticals, and more.

Theft Prevention: Their design deters theft and unauthorized access, providing peace of mind for retailers and logistics providers.

Inventory Control: The unique identification and tracking systems ensure efficient inventory management, reducing the risk of loss or misplacement.

Traceability: Security crates with tracking technology allow businesses to trace the movement of goods, enhancing transparency and accountability.

Benefits

Retail Industry: Security crates are used in retail stores to secure high-value merchandise, preventing theft and ensuring the safety of expensive items.

Logistics and Transport: In the logistics sector, security crates are essential for the transportation of valuable goods, protecting them from theft and damage.

Banking and Financial Institutions: These crates are employed for the secure transportation of currency, confidential documents, and valuable assets.

Pharmaceuticals and Healthcare: In the healthcare industry, security crates help maintain the integrity and security of medications and medical equipment.

Electronics Manufacturing: High-value electronic components and devices are often transported and stored in these crates to protect them from theft and damage.

Security crates are an invaluable solution for businesses dealing with high-value assets and sensitive goods. Their design and features ensure the protection of valuable items throughout the supply chain, and their traceability features offer transparency and accountability.

Euro Crates: The Standardized Solution for Automotive Parts and Retail Supply Chains

Euro crates, characterized by their standardized design, play a critical role in the efficient and organized storage and transportation of goods. Let’s take a closer look at these crates and their significance in automotive parts and retail supply chains:

Standardized Design

Consistent Dimensions: Euro crates adhere to a standardized set of dimensions, allowing them to be easily interchanged and stacked uniformly. This standardization ensures compatibility across various applications.

Stackable and Nestable: Euro crates are designed for both stacking and nesting, optimizing space utilization and simplifying storage and transportation.

Importance in Retail Supply Chains

Efficient Merchandising: Retailers utilize Euro crates for the efficient merchandising of products. These crates are stackable, making it easy to create attractive and organized displays.

Quick Restocking: The standardized size of Euro crates simplifies restocking store shelves, reducing downtime and improving the shopping experience for customers.

Returnable Packaging: Euro crates are often used as returnable packaging in the retail sector, promoting sustainability and reducing waste.

Applications

Automotive Industry: Euro crates are used extensively in the automotive sector for the storage and transportation of spare parts, facilitating streamlined production and assembly processes.

Retail and Supermarkets: These crates are prevalent in retail and supermarkets for displaying and organizing a wide range of products, from groceries to electronics.

Distribution Centers: Euro crates are utilized in distribution centers for sorting and organizing goods, enabling efficient order fulfillment and shipping.

Manufacturing: Manufacturers employ Euro crates to streamline their production processes and ensure a well-organized inventory of components and materials.

Euro crates are synonymous with efficiency, making them the preferred choice for many industries, particularly in automotive parts and retail supply chains. Their standardized dimensions, stackability, and compatibility have simplified storage, transportation, and merchandising processes, contributing to the overall productivity and success of these industries.

Stack and Nest Crates: Versatile Space-Saving Solutions for Logistics and Storage

Stack and nest crates are the unsung heroes of efficient storage and transportation. These crates are designed to maximize space utilization through their unique stacking and nesting capabilities, making them indispensable in various industries. Let’s delve into the details of these versatile crates:

Design and Features

Stackable: Stack and nest crates are designed to securely stack on top of one another when loaded. This vertical stacking optimizes storage space, reducing the footprint required for storage.

Nestable: When empty or not in use, these crates can be nested inside each other. This nesting feature significantly reduces the space required for storage and return transportation.

Durability: Like other plastic crates, stack and nest crates are made from sturdy and durable materials, ensuring they can withstand the rigors of logistics and warehousing.

Benefits

Space Efficiency: The ability to stack and nest crates maximizes space efficiency in warehouses, distribution centers, and transportation.

Cost Savings: Businesses can reduce storage costs by requiring less space for storing both empty and loaded crates, as well as minimizing the number of return trips needed to collect empty crates.

Improved Organization: Stacked and nested crates allow for organized storage and easy access to items, streamlining inventory management and order fulfillment.

Eco-Friendly: The space-saving design of these crates contributes to environmental sustainability by reducing the carbon footprint associated with transportation.

Applications

Logistics and Distribution: Stack and nest crates are used for the transportation of various goods, optimizing the use of cargo space in trucks and shipping containers.

Warehousing: These crates are a favorite choice in warehouses, where space optimization and organized storage are essential for efficient operations.

Agriculture and Harvesting: In the agricultural sector, stack and nest crates are used for collecting and transporting fruits, vegetables, and other crops.

Manufacturing: Manufacturers use these crates for storing and transporting raw materials and finished products, minimizing storage space requirements.

Retail: Retailers employ stack and nest crates for organizing and displaying products, particularly in backroom storage and replenishment processes.

Stack and nest crates are a practical and versatile solution for businesses looking to optimize their storage and transportation operations. Their unique design significantly reduces space requirements, leading to cost savings and more efficient logistics and warehousing processes.

Bread Crates: Enhancing the Art of Bakery and Pastry Transportation in the Food Industry

Bread crates are specifically designed to address the unique needs of the bakery and pastry industry, where the delicate nature of baked goods requires careful handling. These crates have proven to be invaluable assets in ensuring the safe transportation of bakery and pastry products. Let’s examine the details of these crates:

Design and Features

Ventilation: Bread crates often incorporate ventilation to allow for proper airflow. This feature helps maintain the freshness of baked goods and prevents condensation, which can affect product quality.

Stackable and Nestable: Bread crates, like many other plastic crates, are designed to be stackable and nestable, allowing efficient use of storage space when not in use.

Hygienic Materials: They are typically made from food-grade, hygienic materials, ensuring that the crates do not contaminate the products they carry.

Benefits

Freshness Preservation: Bread crates are engineered to maintain the freshness and quality of bakery and pastry products during transportation, helping to preserve their taste and texture.

Damage Prevention: These crates provide sturdy support and protection for baked goods, preventing crushing, breakage, or deformation during handling and transit.

Hygiene and Safety: The use of food-grade materials ensures that the crates do not compromise the hygiene and safety of bakery and pastry items.

Efficiency: The stackable and nestable design of bread crates enhances the efficiency of storage and transportation processes, contributing to cost savings.

Applications

Bakery and Pastry Shops: Bread crates are a common choice for bakeries and pastry shops to transport freshly baked products from the kitchen to the sales floor or distribution centers.

Wholesale and Distribution: These crates are essential for the wholesale distribution of bakery items to restaurants, cafes, and supermarkets.

Food Service Providers: Caterers and food service providers use bread crates to transport large quantities of bakery products to events and venues.

Food Manufacturing: In food manufacturing, these crates are employed to transport dough, ingredients, and semi-finished bakery items.

Supermarkets and Retail Chains: Large supermarket chains use bread crates for organized storage and display of bakery and pastry products.

Bread crates are an indispensable tool for the bakery and pastry industry. Their design ensures that delicate baked goods are transported safely and hygienically, while their space-saving features contribute to efficiency and cost-effectiveness. These crates are a testament to the commitment to preserving the quality and taste of bakery and pastry products from kitchen to consumer.

Plastic Crates for Peaches and Grapes: Preserving Freshness and Integrity in the Fruit Industry

Plastic crates tailored for peaches and grapes play a pivotal role in the fruit industry, where the maintenance of fruit quality during transportation and storage is of utmost importance. These crates are purpose-built to ensure that peaches and grapes reach their destination in optimal condition. Let’s delve into the details of these crates

Design and Features

Ventilation and Drainage: Plastic crates for peaches and grapes typically feature a well-ventilated design to allow for proper airflow. This helps regulate temperature and humidity, reducing the risk of moisture buildup. They also have drainage holes to prevent excess water accumulation.

Gentle Handling: The crates are designed to provide gentle and cushioned support to fruits, reducing the risk of bruising and damage during handling and transportation.

Stackable: Like other plastic crates, they are stackable, optimizing space utilization during storage and transportation.

Benefits

Freshness Preservation: The ventilated design of these crates maintains the freshness and quality of peaches and grapes. It prevents condensation and mold growth, which can compromise fruit quality.

Reduced Damage: The crates’ gentle handling minimizes bruising and damage to fruits, ensuring that they are presented to consumers in the best possible condition.

Efficient Packaging: The stackable feature allows for efficient packaging, reducing the need for excessive packaging materials and optimizing space utilization.

Hygiene and Safety: These crates are typically made from food-grade materials, ensuring that the fruits remain free from contamination.

Applications

Orchards and Farms: Plastic crates for peaches and grapes are used at orchards and farms during harvesting, allowing for efficient collection and transportation of fruit.

Packaging and Distribution Centers: These crates are employed in packaging and distribution centers to sort, pack, and prepare fruits for distribution.

Grocery Stores and Supermarkets: Supermarkets use these crates for the display of peaches and grapes, ensuring that they are presented attractively to customers.

Fruit Export: In the export of fruits, these crates are essential for ensuring that the produce reaches international markets in excellent condition.

Plastic crates for peaches and grapes are integral to the fruit industry’s success. Their well-ventilated and gentle handling design ensures that fruits remain fresh and undamaged throughout the supply chain. Whether you are a farmer, distributor, retailer, or involved in international fruit trade, these crates are a reliable choice for preserving the quality and taste of peaches and grapes.

Heavy Duty Plastic Collapsible Crates: Versatile Space-Saving Solutions for Demanding Logistics and Storage

Heavy-duty plastic collapsible crates are a remarkable innovation in logistics and storage. These crates offer durability, flexibility, and space-saving benefits. Let’s explore their design and applications in detail

Design and Features

Robust Construction: Heavy-duty collapsible crates are built to withstand heavy loads and rough handling. They are typically made from high-quality, impact-resistant plastic materials.

Collapsible Design: One of their standout features is the ability to collapse or fold flat when not in use, saving valuable space during return transportation or storage.

Integrated Handles: Many of these crates include integrated handles for ease of handling and transportation.

Benefits

Durability: These crates are designed to last, making them ideal for repeated use in demanding environments, including warehouses and distribution centers.

Space Efficiency: The collapsible design significantly reduces the space required for storage and return transportation, contributing to cost savings.

Flexibility: Their versatility allows them to adapt to various storage and transportation needs, from bulk storage to organizing smaller items.

Environmentally Friendly: Collapsible crates contribute to sustainability efforts by reducing the need for excessive packaging and their impact on transportation-related emissions.

Applications

Warehousing: Heavy-duty collapsible crates are a staple in warehousing operations for efficient storage and organization of goods.

Retail Distribution: They play a crucial role in retail distribution, streamlining the movement of products from distribution centers to stores.

Automotive Industry: These crates are used for storing and transporting automotive parts and components.

E-commerce and Fulfillment Centers: In the world of e-commerce, collapsible crates facilitate order fulfillment, optimizing storage and transportation processes.

Agriculture: Farmers use these crates for the collection and storage of harvested produce, streamlining agricultural processes.

Heavy-duty plastic collapsible crates are versatile workhorses in logistics and storage. Their robust design, space-saving features, and adaptability make them a valuable asset for businesses looking to optimize storage and transportation efficiency while maintaining durability and reliability.

Summary

In this article, we’ve delved deep into various types of plastic crates, essential tools for logistics and storage in different industries. From ventilated vegetable crates to sealed industrial crates, security crates, standardized Euro crates, stack and nest crates, and specialized crates for bakery and fruit transportation, we’ve explored the design features and applications of these crates. We’ve also introduced heavy-duty collapsible plastic crates, offering space-saving solutions for demanding logistics and storage needs.

Whether you’re a farmer, manufacturer, retailer, construction professional, or logistics expert, selecting the right plastic crates is crucial for your business. These crates can enhance efficiency, protect your products, and reduce costs. If you’re in search of the right plastic crates for your needs, don’t hesitate to reach out to our expert team. We’ll provide customized solutions tailored to your specific requirements, ensuring you get the best logistics and storage solutions.

Don’t miss this opportunity; take action now to optimize your logistics and storage processes. Contact us and let us assist you in choosing the plastic crates that are perfect for your business, improving efficiency, and achieving success.