Industrial Plastic Trays

Discover the ultimate resource for industrial plastic trays – optimizing storage, transport, and organization. Explore benefits, customization, applications, and more. Elevate your industrial efficiency now.

Welcome to the ultimate guide page dedicated to industrial plastic trays – versatile solutions that streamline storage, organization, and transport in various industrial settings. In this comprehensive guide, we delve into the world of industrial plastic trays, providing you with a deep understanding of their features, benefits, applications, and customization options. Explore how these trays elevate efficiency, enhance workflow, and contribute to well-organized industrial operations.

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the download link immediately.

Introduction to Industrial Plastic Trays

Definition of industrial plastic trays

Industrial plastic trays are specialized containers meticulously crafted from durable plastic materials, designed to optimize the storage, handling, and organization of a wide range of items in industrial settings. These trays are characterized by their versatile design, structural integrity, and ergonomic features, making them indispensable tools for efficient material transport, streamlined workflow, and enhanced organization within various industries. Industrial plastic trays come in various sizes, configurations, and load capacities, catering to diverse operational needs and contributing to the overall efficiency and productivity of industrial processes.

Main advantages you can get

- Versatility: Adaptable for various materials, aiding organization and transport.

- Durability: Robust plastic construction withstands industrial demands, ensuring long-term use.

- Ergonomic Design: Comfortable handling, stackable for space efficiency.

- Customization: Tailored sizing, colors, and features optimize workflow and branding.

- Hygienic: Easy to clean, suitable for industries with stringent hygiene standards.

- Efficient Organization: Facilitates orderly storage, quick access, and inventory control.

- Reduced Damage: Minimizes material handling risks, preventing breakage and loss.

- Enhanced Workflow: Smooth movement of goods, reducing delays and bottlenecks.

Mtcplast Industrial Plastic Tray Series

Want to purchase plastic pallets onboard? This ultimate solution guide would help you everything about buying products.

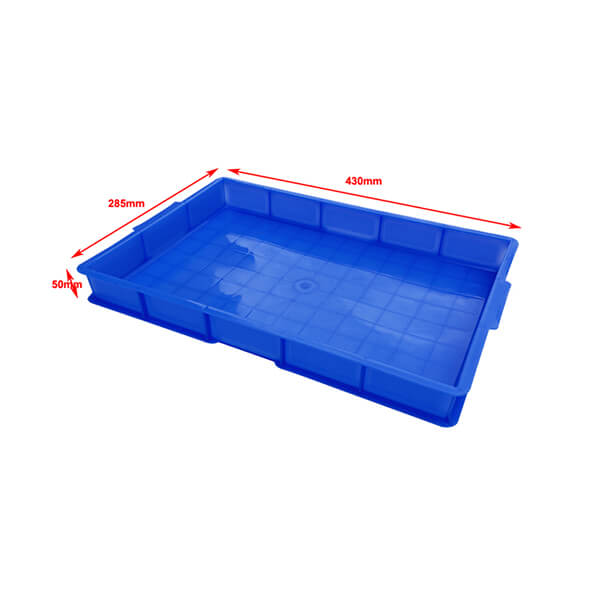

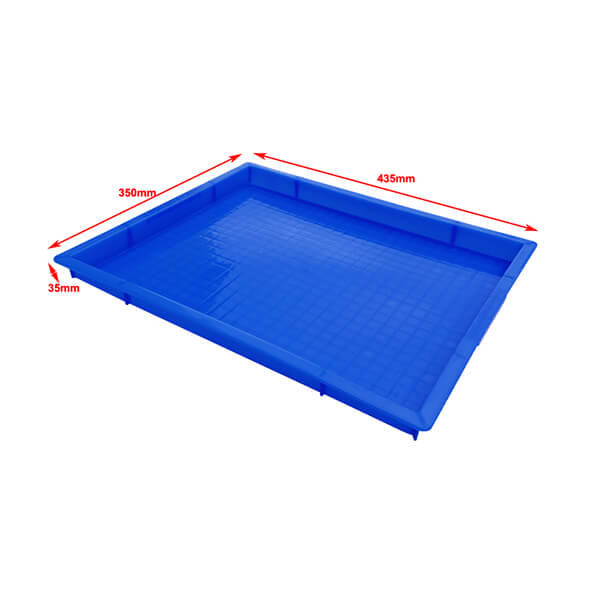

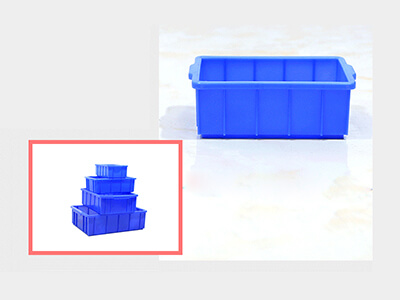

Outer Dimension: 345*245*65mm

Inner Dimension:345*220*58mm

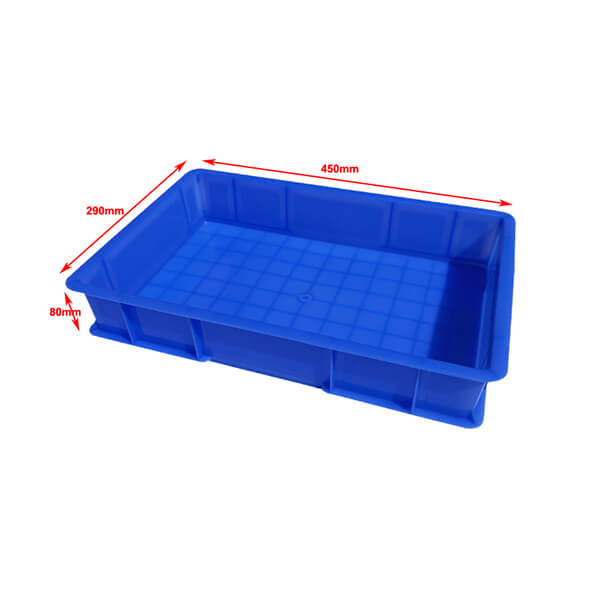

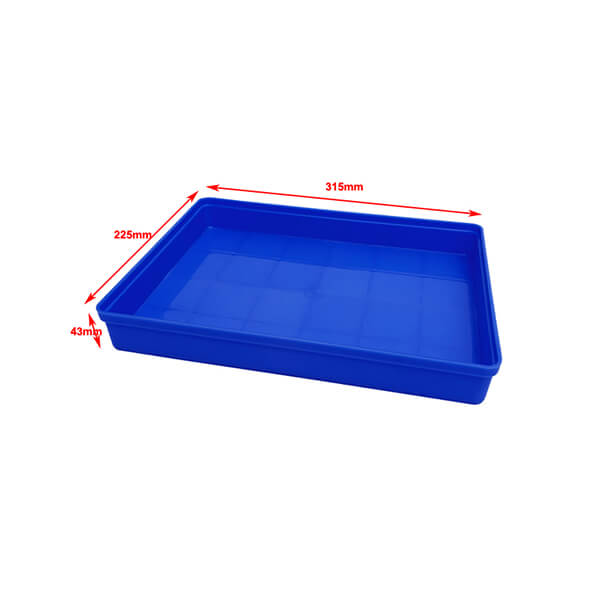

Outer Dimension: 450*290*80mm

Inner Dimension:400*260*78mm

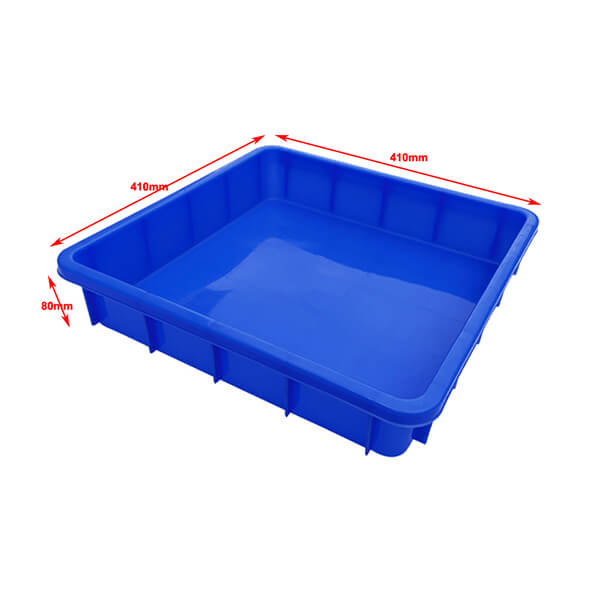

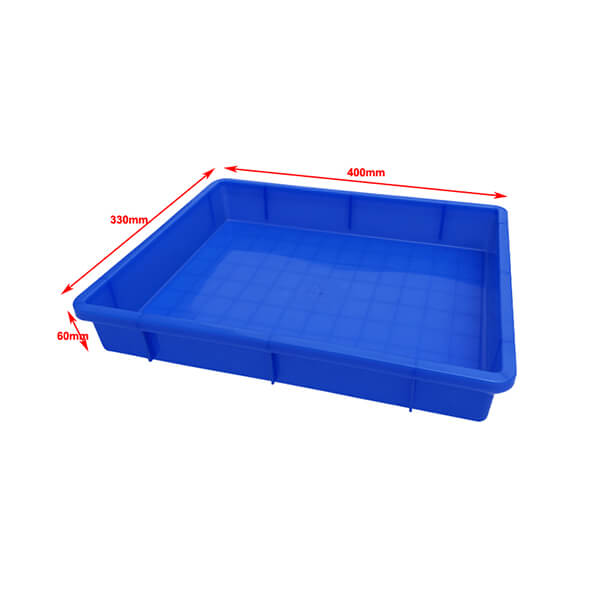

Outer Dimension: 560*380*80mm

Inner Dimension:530*340*70mm

Outer Dimension: 610*420*95mm

Inner Dimension:568*380*85mm

Dimension:1160*1160*160

Rack Load:5000kg

Dynamic Load:5000 kg

Rack Load:1500kg

Dimension:1160*1160*160

Rack Load:5000kg

Dynamic Load:5000 kg

Rack Load:1500kg

Dimension:1160*1160*160

Rack Load:5000kg

Dynamic Load:5000 kg

Rack Load:1500kg

Dimension:1160*1160*160

Rack Load:5000kg

Dynamic Load:5000 kg

Rack Load:1500kg

Dimension:1160*1160*160

Rack Load:5000kg

Dynamic Load:5000 kg

Rack Load:1500kg

Dimension:1160*1160*160

Rack Load:5000kg

Dynamic Load:5000 kg

Rack Load:1500kg

Benefits of Industrial Plastic Trays

Industrial plastic trays stand as transformative assets, revolutionizing diverse industries with a spectrum of advantages. Delve into the array of benefits that these trays bestow upon industrial environments, showcasing their pivotal role in enhancing operational efficiency and optimizing resource utilization.

Durability Redefined

Industrial plastic trays are engineered to endure the rigors of demanding industrial settings. Their robust construction ensures resistance to impacts, corrosion, and wear, leading to longevity and cost-effective solutions that withstand the test of time.

Streamlined Maintenance

Experience the ease of maintenance with industrial plastic trays. Their smooth, non-porous surfaces simplify cleaning, minimizing downtime and ensuring a hygienic work environment conducive to efficient operations.

Prevention of Material Damage

Industrial plastic trays act as protective shields, reducing the risk of damage during handling and transport. This safeguarding of materials ensures product integrity and minimizes wastage.

Environmental Responsibility

Eco-friendly materials used in industrial plastic trays align with sustainable practices. Choosing these trays contributes to reducing environmental impact while maintaining high functionality and performance.

Ergonomic Excellence

Enhance ergonomic practices with trays designed for comfortable handling. Ergonomically shaped handles reduce strain on workers, promoting smoother material transport and optimizing overall workflow efficiency.

Customized Efficiency

Embrace tailored solutions by customizing industrial plastic trays to match specific operational needs. By selecting the right size, color, and features, you optimize workflow efficiency and ensure seamless integration into your unique industrial environment.

Efficient Space Utilization

Maximize space utilization with stackable industrial plastic trays. Their space-saving design optimizes storage capacity, reducing clutter and creating an organized workspace that promotes productivity.

Versatile Applications

From manufacturing floors to distribution centers, industrial plastic trays seamlessly adapt to diverse applications. Their versatility spans across industries, providing customizable solutions for storage, transport, and organization.

Increased Operational Speed

Swift and effortless material movement is facilitated by the design of industrial plastic trays. These trays reduce time spent searching for items, accelerating material handling processes, and boosting overall operational speed.

Premium Material Selection

We meticulously choose high-quality, brand-new materials to ensure production quality and provide outstanding durability, with a strong resistance to pressure and wear.

Durable and Wear-Resistant

Resistant to extreme temperatures, wear, and pressure, ensuring robust performance in various demanding environments.

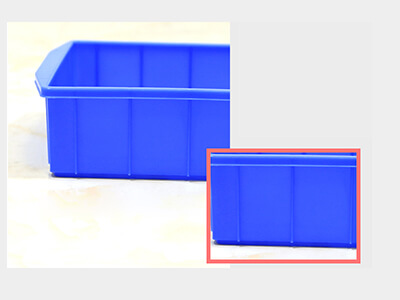

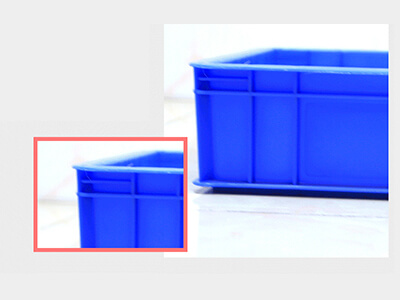

Reinforced Handle Design

Ergonomically designed handles with reinforced grips for enhanced stability and slip resistance

Durable Structure

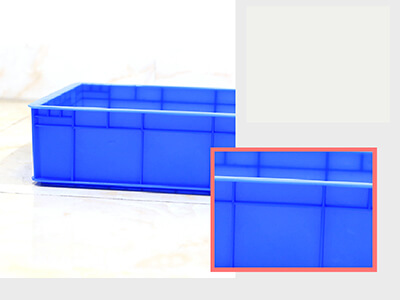

External reinforcements provide a sturdy construction, preventing deformation and significantly increasing product lifespan

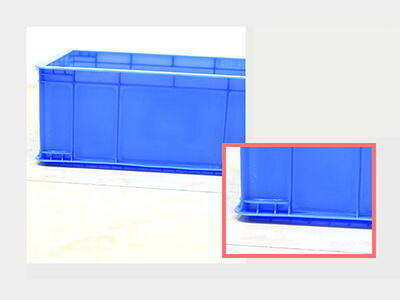

Reinforced Bottom Grid

The bottom of the tray features a thickened design with a high-density reinforcement grid, ensuring stability, resistance to deformation, and extended lifespan.

One-Piece Injection Molding

Utilizing a single-step injection molding process, these trays eliminate issues such as moisture damage, deformation, wear, and crushing during transport, thereby extending their lifespan and serving as a sustainable alternative to cardboard boxes.

Versatility Across Applications

Embark on a journey of exploration as we uncover the remarkable adaptability of industrial plastic trays across a spectrum of industries. From manufacturing plants to distribution centers, discover how these versatile trays seamlessly integrate into various operational contexts, redefining efficiency, organization, and workflow.

Manufacturing Excellence

In manufacturing, industrial plastic trays serve as indispensable companions on production lines. They hold components, tools, and work-in-progress items, ensuring easy access, reducing downtime, and promoting efficient assembly processes.

Warehousing and Distribution

Industrial plastic trays take center stage in distribution centers, simplifying sorting, storage, and transport. Their stackable design optimizes storage space, streamlining logistics and expediting the movement of goods.

Retail Optimization

Within retail environments, industrial plastic trays contribute to orderly displays and storage of merchandise. These trays enhance visual appeal, facilitate restocking, and ultimately enhance the shopping experience for customers.

Agriculture and Horticulture

On farms, these trays prove invaluable for harvesting, transporting, and organizing produce. Their durability and easy-clean properties adapt seamlessly to outdoor settings, aiding in crop management.

Healthcare and Pharmaceuticals

In sterile environments, industrial plastic trays provide hygienic storage for medical supplies and pharmaceuticals. Their easy-clean surfaces and organizational attributes promote compliance with strict hygiene standards.

Food Processing and Culinary Arts

From food processing to commercial kitchens, industrial plastic trays aid in ingredient organization, food preparation, and storage. Their clean, durable design supports safe and efficient culinary operations.

Electronics and Manufacturing

Delicate electronics find secure housing in these trays, safeguarded from electrostatic discharge and physical damage. Their protective design ensures the integrity of sensitive components.

Automotive and Repair Workshops

Industrial plastic trays are essential in automotive settings, organizing tools, parts, and equipment. Their resilience against oil, grease, and mechanical stress ensures durability in demanding repair environments.

Textile and Garment Industry

These trays play a role in textile and garment manufacturing, keeping fabrics and materials organized during production. Their efficient storage and organization enhance manufacturing processes.

Unlock the Possibilities of Exceptional Industrial Plastic Trays, Exclusively with Mtcplast

Partnering with Mtcplast

At Mtcplast, we go beyond being a supplier – we are your strategic partner in optimizing industrial operations through cutting-edge industrial plastic trays. In this chapter, embark on a journey to understand why we stand as your trusted ally, offering unparalleled quality, customization, and unwavering customer support tailored to your unique industrial requirements.

Unparalleled Quality

Our industrial plastic trays are the epitome of quality and reliability. Meticulously crafted from premium materials, they undergo rigorous testing to ensure durability, structural integrity, and long-term performance. When you choose [Your Company Name], you choose trays that withstand the most demanding industrial environments, delivering consistent results that elevate efficiency and organization.

Customization to Suit Your Vision

Recognizing the diversity of industrial needs, we empower you with customization options that bring your vision to life. From dimensions to colors, branding to labeling, our industrial plastic trays adapt seamlessly to your workflow and operational aesthetics. Your trays become an extension of your identity, harmonizing functionality and visual appeal.

Expert Consultation and Support

Navigating the selection process is made effortless with our expert consultation. Our team of professionals is dedicated to understanding your unique requirements, providing tailored recommendations that align with your operational goals. From load capacities to ergonomic design, we guide you towards the optimal tray solutions that enhance your efficiency.

Commitment to Excellence

At Mtcplast, excellence is not just a value; it’s our foundation. We are committed to delivering solutions that exceed expectations, ensuring that every industrial plastic tray embodies our dedication to quality, innovation, and precision. Your success is our priority, and we are relentless in our pursuit of perfection.

Collaboration for Success

Beyond being a supplier, we view our relationship as a collaboration aimed at propelling your industrial endeavors forward. We immerse ourselves in your challenges, goals, and aspirations, leveraging our expertise to provide solutions that drive efficiency, enhance organization, and contribute to your overall success.

Empower Your Industrial Future

Choosing Mtcplast as your partner for industrial plastic trays is a decision that echoes in every aspect of your operations. Experience trays that seamlessly blend form and function, optimizing your efficiency while aligning with your brand’s identity. Unlock a world of possibilities where industrial plastic trays transcend utility and become catalysts for innovation and growth.

As you delve deeper into this chapter, you’ll discover firsthand how our partnership enriches your industrial experience. Experience the fusion of technology, quality, and personalized support that only Mtcplast can offer. Together, we embark on a journey of industrial transformation, where exceptional trays are just the beginning of what we can achieve together.

Unlocking Uniqueness: Tailoring Industrial Plastic Trays to Your Vision

Customization for Your Operations

In this chapter, we delve into the world of customization, where industrial plastic trays become a canvas for realizing your operational vision. Discover an array of options that allow you to align trays perfectly with your workflow and unique requirements, elevating efficiency, organization, and aesthetic appeal.

Sizing to Precision

Customizing the size of industrial plastic trays is the foundation of a seamless fit within your operational environment. Whether accommodating specific materials, shelf dimensions, or storage spaces, selecting the right size ensures optimal utilization and space efficiency.

Colors that Reflect Your Identity

Industrial plastic trays offer a diverse palette of colors, allowing you to incorporate branding elements or align with color-coded workflows. Choosing colors that resonate with your operational identity enhances visual appeal while aiding quick identification.

Ergonomic Innovations

Enhance functionality by tailoring trays with ergonomic features. Opt for comfortable handles, stackable designs, or specialized dividers that align with your handling processes, reducing strain on workers and streamlining material transport.

Labeling for Precision

Incorporate labeling options that facilitate accurate item identification and inventory control. Customized labeling ensures quick retrieval, minimizes errors, and contributes to a well-organized and efficient workspace.

Inserts and Dividers

Custom inserts and dividers transform industrial plastic trays into specialized compartments. Create dedicated sections for different materials, components, or products, optimizing organization and preventing cross-contamination.

Branded Solutions

Elevate your brand presence by incorporating logos, company names, or distinctive markings on industrial plastic trays. Branded trays not only unify your operational aesthetics but also leave a lasting impression on clients and stakeholders.

Material Selection

Customize trays by selecting materials that align with your industry’s demands. Whether it’s resistance to chemicals, extreme temperatures, or other challenges, tailored material choices ensure trays endure your specific operational environment.

Collaborative Consultation

At Mtcplast, our experts collaborate closely with you to understand your customization needs. We offer expert guidance to help you make informed decisions, ensuring that each customization option enhances your operational efficiency.

A Truly Tailored Solution

Customizing industrial plastic trays isn’t just about aesthetics – it’s about creating a solution that mirrors your operational goals. From ergonomics to branding, each customization option enhances functionality, optimizing workflow, and contributing to a cohesive industrial ecosystem.

Your Vision Realized

By embracing customization, industrial plastic trays transcend being mere tools. They become integral components that embody your operational ethos, seamlessly aligning with your processes and enhancing your unique industrial landscape.

Steps to Work with Us

Working with us is a straightforward process designed to ensure a smooth experience for our customers. Here are the steps to work with us:

Contact and Consultation

Reach out to us through our website, email, or phone to initiate the conversation. Our responsive team will be available to answer your inquiries, discuss your requirements, and provide any necessary guidance or clarification. We will gather essential details about your needs, such as pallet specifications, quantities, customization requirements, and desired timelines.

Quotation

Based on the information provided, we will prepare a comprehensive quotation tailored to your specific requirements. The quotation will include details such as pricing, delivery timelines, customization options, and any additional services or support you may require. We strive to offer competitive pricing and transparent information to assist you in making an informed decision.

Order Confirmation

Once you review the quotation and are ready to proceed, confirm your order by accepting the quotation and making the necessary arrangements, such as providing payment details and signing any required documentation. Our team will guide you through this process and address any questions or concerns you may have.

Manufacturing and Customization

Our skilled manufacturing team will begin the production process according to the agreed-upon specifications. If you have requested any customization, such as size variations, color choices, or branding options, our experts will ensure that your pallets are tailored to your specific needs. Throughout the manufacturing process, we maintain stringent quality control measures to ensure the highest standards are met.

Quality Assurance and Inspection

Before shipment, our quality assurance team will thoroughly inspect the finished plastic pallets to ensure they meet our rigorous quality standards. This inspection process includes checking for any defects, verifying dimensions and load capacities, and ensuring compliance with any requested customization.

Shipping and Delivery

Once the quality inspection is completed, we will arrange the shipping and delivery of your plastic pallets. We work with trusted logistics partners to ensure prompt and reliable delivery to your desired location. Shipping times may vary depending on the destination and shipping method chosen. We will provide you with tracking information so you can monitor the progress of your shipment.

After-Sales Support

Our commitment to your satisfaction extends beyond the delivery of your plastic pallets. We offer comprehensive after-sales support to address any post-delivery questions, concerns, or issues that may arise. Our dedicated customer support team is available to assist you with any further inquiries, technical guidance, or ongoing collaboration.

Unlocking Clarity: Your Guide to Understanding Industrial Plastic Trays

Answering Your Questions

In this informative chapter, we address the most common inquiries surrounding industrial plastic trays, dispelling doubts and illuminating the path to informed decision-making. Explore a comprehensive array of questions, from functionality to maintenance, providing you with the insights you need to harness the full potential of these versatile tools.

What Are Industrial Plastic Trays Used For?

Industrial plastic trays are utilized across industries for efficient material handling, organization, and storage. They enhance workflow in manufacturing, distribution, healthcare, and more, ensuring streamlined operations and optimized resource utilization.

How Durable Are Industrial Plastic Trays?

Crafted from robust materials, industrial plastic trays exhibit exceptional durability. They withstand impacts, resist corrosion, and remain resilient in challenging environments, providing a long-lasting solution for various industrial applications.

Can Industrial Plastic Trays Be Customized?

Absolutely. Industrial plastic trays offer a spectrum of customization options, from sizing and colors to branding and labeling. Tailoring trays to your unique requirements enhances organization, aligns with your brand, and optimizes workflow.

What Are the Maintenance Requirements?

Maintaining industrial plastic trays is straightforward. Their smooth, non-porous surfaces make cleaning easy. Regular cleaning with mild detergents ensures a hygienic work environment and prolongs the trays’ lifespan.

Can Industrial Plastic Trays Withstand Harsh Chemicals?

Industrial plastic trays can be selected with materials that resist chemicals and harsh substances, ensuring they endure challenging industrial environments without compromise.

These Trays Suitable for Food Handling?

Yes, industrial plastic trays designed for food handling comply with hygiene standards. Their easy-clean surfaces and durability make them suitable for organizing, preparing, and transporting food items.

How Do Industrial Plastic Trays Compare to Other Materials?

Compared to traditional materials, industrial plastic trays offer advantages of durability, customization, and ease of maintenance. They are lightweight, resistant to corrosion, and provide a cost-effective solution.

How Can I Select the Right Size of Tray?

Choosing the right size involves assessing your items’ dimensions and available space. Our expert team can guide you through the selection process, ensuring optimal sizing for your specific operational needs.

As you delve into this FAQ section, you’ll gain a comprehensive understanding of industrial plastic trays, addressing concerns and clarifying their role in elevating industrial efficiency. Each answer empowers you with the knowledge needed to make informed choices, unlocking the full potential of these versatile tools.

Elevate Efficiency and Durability with MTCPlast's Industrial Plastic Trays!

Ready to transform your industrial operations? Contact Mtcplast to explore our comprehensive range of industrial plastic trays. Request a quote, consult with our experts, and take the first step toward optimizing your storage and handling processes.

Why should you choose MTCPlast’s Industrial Plastic Trays for your operations? Let us highlight the customer-centric advantages:

- Unparalleled Durability: Our Industrial Plastic Trays are engineered to withstand the toughest environments. You can count on them for years, reducing the frequency of replacements and saving you money.

- Easy Maintenance: Spend more time on your core tasks, not maintenance. The trays are incredibly easy to clean, ensuring hygiene standards are met with minimal effort.

- Ergonomic Design: Your team deserves equipment that works with them, not against them. Our trays are designed with ergonomics in mind, reducing strain and enhancing productivity.

- Space Optimization: In any workspace, space is precious. Our trays are stackable and nestable, allowing you to maximize your storage area and overall efficiency.

- Versatility Across Industries: From manufacturing to distribution, our trays adapt seamlessly to various applications, streamlining processes and improving overall productivity.

- Customization: No two businesses are the same. That's why we offer a range of customizable options, including size, color, and features, ensuring our trays meet your unique operational needs.

- Exceptional Customer Support: When you partner with MTCPlast, you're not just getting trays; you're gaining a dedicated partner. We provide top-notch customer support to ensure your satisfaction and success.