Picking Bins

Optimize your order picking and organization with our convenient picking bins. Designed for easy access and quick identification of items, these bins streamline the picking process, improving efficiency in warehouses and distribution centers.

Picking bins, also known as order picking bins or storage bins, are essential tools in modern warehousing and logistics. Designed to enhance efficiency and organization, these versatile bins play a crucial role in the order fulfillment process, manufacturing, retail, and beyond.

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the download link immediately.

What are Picking Bins?

Definition and Purpose of Picking Bins

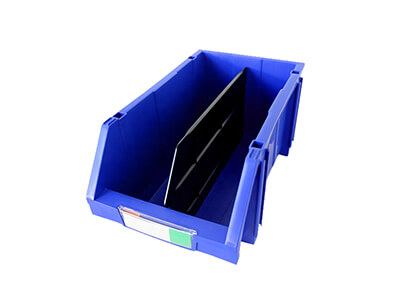

Picking bins, at their core, are specialized containers designed to facilitate the efficient picking and packing of items within a warehouse or storage facility. They come in various sizes, configurations, and materials to suit different industries and applications.

- Accelerated Fulfillment: Picking bins reduce search time, ensuring quick access to items. Expedited order picking leads to faster customer satisfaction.

- Error Reduction: Clear labeling and organized storage minimize picking mistakes, reducing returns and enhancing accuracy.

- Space Optimization: Stackable and nestable designs maximize storage capacity, utilizing both floor and vertical space efficiently.b

- Customizable Solutions: Picking bins offer customization options, tailored to your needs, branding, and workflow, ensuring a seamless fit for your operations.

Item No | Outer Dimension W×D×H(mm) | Outer Dimension W×D×H(inch) | N.W. (kg) | Load (kg) | Qty/ctn (pcs) | Qty/20’GP (ctn) | Qty/40’HQ (ctn) |

PK-001 | 100×160×74 | 4×6-3/10×2-9/10 | 0.12 | 3 | 50 | 576 | 1312 |

PK-002 | 150×240×124 | 5-9/10×9-2/5×4-4/5 | 0.28 | 8 | 36 | 176 | 436 |

PK-003 | 200×340×150 | 7-4/5×13-2/5×5-9/10 | 0.63 | 15 | 18 | 177 | 446 |

PK-004 | 200×450×175 | 7-4/5×17-7/10×6-9/10 | 0.79 | 30 | 12 | 168 | 396 |

PK-005 | 300×450×175 | 11-4/5×17-7/10×6-9/10 | 1.03 | 50 | 8 | 183 | 410 |

PK-006 | 107×185×77 | 4-1/5×7-3/10×3 | 0.14 | 4 | 64 | 336 | 785 |

PK-007 | 214×280×175 | 8-2/5×11×6-9/10 | 0.5 | 22 | 16 | 192 | 480 |

PK-008 | 214×370×175 | 8-2/5×14-3/5×6-9/10 | 0.69 | 27 | 8 | 292 | 709 |

PK-010 | 420×370×175 | 16-1/2×14-3/5×6-9/10 | 1.04 | 35 | 4 | 336 | 780 |

PK-021 | 280×350×184 | 11×13-3/4×7-1/4 | 0.89 | 30 | 8 | 201 | 512 |

PK-022 | 280×425×260 | 11×16-3/4×10-1/4 | 1.29 | 35 | 8 | 110 | 268 |

PK-023 | 365×450×180 | 14-2/5×17-7/10×7 | 1.2 | 35 | 8 | 129 | 315 |

PK-024 | 400×600×220 | 15-3/4×23-3/5×8-2/3 | 2 | 40 | 8 | 82 | 195 |

Key Features&Benefits of Using Picking Bins

Picking bins, often considered the unsung heroes of efficient warehousing and logistics, bring a plethora of advantages to your operations. These benefits not only streamline your order fulfillment process but also contribute to a more organized, cost-effective, and productive warehouse environment. Let’s delve deeper into the remarkable benefits that picking bins offer

Accelerated Order Fulfillment

Picking bins are meticulously designed to optimize the order picking process. By providing a dedicated space for each SKU or product, they eliminate the time-consuming search for items, resulting in faster and more accurate order picking. Employees can quickly locate the required items, leading to reduced processing times and improved order turnaround.

Reduced Labor Costs

Efficiency is synonymous with cost savings. Picking bins reduce the need for excessive manual labor by facilitating a streamlined workflow. With items neatly organized and easily accessible, warehouse staff spend less time searching for products and more time on value-added tasks. This efficiency leads to a significant reduction in labor costs, allowing your team to focus on higher-priority tasks.

Flexibility and Customization

Picking bins come in a variety of sizes, shapes, and configurations to suit your specific needs. This flexibility allows you to tailor your storage solution to match your inventory and warehouse layout. Whether you need small bins for fast-moving items or larger bins for bulk storage, the customization options are virtually endless.

Improved Space Utilization

Maximizing space is a constant challenge in warehousing. Picking bins are expertly crafted to make the most of your available storage area. Their stackable and nestable designs enable vertical storage, optimizing the use of both floor and shelf space. This space efficiency translates to higher storage capacity, reducing the need for expansion and minimizing real estate costs.

Enhanced Safety and Ergonomics

Safety is paramount in any warehouse setting. Picking bins are designed with ergonomic features, such as comfortable handles and smooth edges, to ensure the well-being of your staff. By minimizing strain and discomfort during the picking process, you create a safer working environment and reduce the risk of workplace injuries.

Enhanced Inventory Management

Maintaining accurate inventory records is essential for efficient operations. Picking bins contribute to accurate inventory tracking by providing a clear visual indication of item quantities. Integrated labeling options allow for easy product identification, minimizing the risk of errors and inventory discrepancies. As a result, you can maintain optimal stock levels and prevent stockouts.

Reduced Errors and Returns:

The organized nature of picking bins minimizes the chances of order picking errors. Employees can clearly see and access the items they need, reducing the likelihood of selecting incorrect products. This accuracy extends to packing, ensuring that the right items are included in each order, ultimately leading to fewer returns and customer dissatisfaction.

Equipped with label and plastic cover

Could be interlocked side by side

Reinforced ribs and bottoms enable large loading capacity

Stackable with connectors, no need rack

Optional deviders are available for some models

Choosing the Right Picking Bins

Selecting the perfect picking bins for your warehouse operation is a pivotal decision that can significantly impact your efficiency and organization. To make an informed choice, it’s essential to consider a range of factors that align with your specific requirements. Let’s explore the key considerations when choosing the ideal picking bins for your needs

Load Capacity

Assess the weight of the items you intend to store in the picking bins. Different picking bins offer varying load capacities, and it’s crucial to select bins that can safely accommodate the weight of your products. Overloading bins can compromise their structural integrity and lead to safety hazards.

Material Durability

The material composition of picking bins plays a critical role in their durability and longevity. Opt for industrial-grade plastics that are known for their resistance to impact, chemicals, and environmental factors. High-quality materials ensure that your picking bins can withstand the rigors of daily use and maintain their integrity over time.

Size and Dimensions

Evaluate the dimensions of the items you plan to store in the picking bins. Choose bins that provide sufficient space for your products while optimizing storage density. Consider different bin sizes to accommodate various item types and quantities, allowing for efficient organization and easy retrieval.

Compatibility with Existing Setup

Ensure that the chosen picking bins seamlessly integrate with your current warehouse setup. They should be compatible with your shelving systems, racking units, and any automated conveyor systems you have in place. Compatibility facilitates a smooth implementation process without the need for extensive modifications.

Nesting and Stackabilit

If space optimization is a priority, look for picking bins that offer nesting and stackability features. Nesting allows bins to fit inside each other when empty, reducing storage requirements. Stackable bins, on the other hand, enable vertical storage, maximizing the use of available space.

Labeling and Identification

Efficient inventory management relies on clear labeling and easy identification. Choose picking bins that feature integrated label holders or slots, making it effortless to label and categorize items. Clear labeling minimizes errors, enhances organization, and accelerates the order picking process.

Customization Options

Consider whether the manufacturer offers customization options for picking bins. This includes the ability to select colors, add company logos, or request specialized features to align with your branding and operational needs.

Long-Term Value

Invest in picking bins that offer long-term value through their durability and versatility. While budget considerations are important, prioritizing quality ensures that your investment pays off over time by reducing replacement and maintenance costs.

User Feedback and Reviews

Research user feedback and reviews for the specific picking bins you’re considering. Learning from the experiences of other businesses can provide valuable insights into the bins’ performance, durability, and suitability for your needs.

Applications of Picking Bins

Picking bins are versatile and adaptable tools that find their place in a wide range of industries and operational contexts. Their ability to enhance organization, streamline processes, and expedite order fulfillment makes them an invaluable asset in various scenarios. Let’s delve into the diverse applications of picking bins and how they excel in optimizing efficiency and productivity

Choosing MTCPLAST for Picking Bins

Selecting the right supplier for your picking bins is a critical decision that directly impacts the efficiency and success of your warehouse operations. When it comes to top-quality picking bins that meet your unique needs, [Your Company Name] stands out as the trusted partner. Here’s why you should choose us for your picking bin requirements

Unparalleled Product Quality:

At Mtcplast we prioritize product quality above all else. Our picking bins are crafted from industrial-grade plastics known for their durability, impact resistance, and longevity. You can trust that our bins will withstand the demands of a bustling warehouse environment, ensuring a long-lasting investment that delivers value for years to come.

Customization to Suit Your Needs

We understand that every warehouse operation is distinct. That’s why we offer customization options that allow you to tailor your picking bins to your specific requirements. Whether it’s selecting colors, adding company logos, or requesting specialized features, we are dedicated to providing you with bins that align perfectly with your branding and operational needs.

Expert Guidance and Support

Choosing the right picking bins can be a complex decision. Our team of experts is here to guide you through the process. We’ll work closely with you to understand your workflow, inventory types, and operational goals. With our industry knowledge and experience, we’ll recommend the most suitable picking bin solutions that optimize efficiency and organization.

Exceptional Customer Support

Your satisfaction is our priority. Our commitment to exceptional customer support ensures that your experience with [Your Company Name] is seamless from inquiry to delivery. We’re available to address your questions, provide insights, and assist you in making informed decisions. Our goal is to exceed your expectations and establish a lasting partnership.

Proven Track Record

Mtcplast has a proven track record of delivering top-quality picking bin solutions to businesses across various industries. Our satisfied customers attest to our dedication to excellence and the value our picking bins bring to their warehouse operations.

Forward-Thinking Solutions

We stay ahead of industry trends and innovations to provide you with cutting-edge solutions. As warehousing and logistics continue to evolve, you can rely on [Your Company Name] to offer forward-thinking products that keep your operation competitive and efficient.

Sustainable Practices

We are committed to sustainability and environmental responsibility. Our picking bins are designed with durability in mind, reducing the need for frequent replacements. Additionally, our production processes adhere to eco-friendly practices, minimizing our carbon footprint.

Comprehensive Range of Products

Beyond picking bins, [Your Company Name] offers a comprehensive range of industrial plastic products designed to enhance your storage and logistics operations. From industrial baskets and trays to euro containers and security crates, we provide solutions that cater to your diverse needs.

Mtcplast is your trusted partner for picking bins that elevate your warehouse management. Our unwavering dedication to product quality, customization, expert guidance, exceptional customer support, and sustainable practices sets us apart as the preferred choice. Choose [Your Company Name] for picking bins that optimize your storage, streamline your operations, and contribute to the success of your business. Contact us today to embark on a journey of warehouse excellence with the best in the industry.

FAQs: Picking Bins Explained

As you embark on your journey to optimize warehouse operations with picking bins, it’s natural to have questions and seek clarity. In this section, we address common questions about picking bins, providing comprehensive insights into their features, benefits, and usage. Let’s explore these FAQs to ensure you have a clear understanding of picking bins

What are picking bins, and how do they differ from regular storage containers?

Picking bins are specialized containers designed for efficient order picking and organization within warehouses. Unlike regular storage containers, picking bins often feature ergonomic handles, label holders, and stackable/nestable designs tailored to streamline the order fulfillment process.

How do picking bins contribute to warehouse efficiency?

Picking bins enhance warehouse efficiency by optimizing space utilization, reducing order picking times, and minimizing errors. Their organized design allows quick access to items, leading to accelerated order fulfillment and improved overall productivity.

What factors should I consider when selecting the right picking bins for my operation?

When choosing picking bins, factors such as load capacity, material durability, size, compatibility with existing setup, and customization options are crucial. Evaluating your specific needs and workflow will guide you towards selecting the most suitable bins.

Can picking bins be customized to match our branding?

Yes, at [Your Company Name], we offer customization options that allow you to add your company logo, choose colors, and tailor features to align with your branding. Customization ensures that your picking bins seamlessly integrate into your warehouse environment.

Are picking bins suitable for different industries beyond warehousing?

Absolutely. Picking bins find applications in various industries, including manufacturing, retail, healthcare, and more. Their versatility and benefits extend to any environment where efficient organization and order picking are essential.

How do picking bins contribute to inventory accuracy?

Picking bins enhance inventory accuracy through clear labeling and organized storage. Integrated label holders allow for easy identification, reducing the risk of errors and ensuring accurate order fulfillment.

Can picking bins be used with automated systems and robotics?

Yes, many picking bins are designed to integrate seamlessly with automated systems and robotics. Their standardized sizes and stackability make them compatible with conveyor systems, robotic arms, and other automation technologies.

What maintenance is required for picking bins?

Picking bins are designed for durability and easy maintenance. Regular cleaning with mild detergents is sufficient to keep them in optimal condition. Their robust construction ensures they can withstand frequent use and cleaning.

How do picking bins contribute to a safer work environment?

Picking bins with ergonomic features, such as comfortable handles and smooth edges, reduce the risk of strain and injuries during handling. Clear organization minimizes the need to reach, bend, or overexert, creating a safer and more ergonomic workspace.

Ready to Elevate Your Warehouse Efficiency? Contact Us Today!

Are you ready to experience the remarkable benefits of picking bins in your warehouse operations? At Mtcplast, we are committed to helping you optimize your storage and logistics with top-quality picking bins. Take the first step towards streamlining your processes, reducing order fulfillment times, and enhancing overall productivity.

Choosing MTCPlast’s Picking Bins isn’t just a purchase; it’s a leap toward an enhanced warehousing experience. Here’s what our Picking Bins bring to you: enhancing overall productivity.

- Maximum Efficiency: Our Picking Bins are designed to optimize your picking process. With easy access and a layout tailored for efficiency, your operations become faster and more productive.

- Organized Warehousing: Bid farewell to cluttered, disorganized spaces. Our bins allow you to create a neat and well-organized warehouse, improving overall storage conditions.

- Durable and Reliable: You can rely on the robust construction of our Picking Bins. They're engineered to withstand heavy use and serve you faithfully for the long haul.

- Easy Handling: User-friendly designs make handling and moving your bins a breeze. This not only enhances efficiency but reduces physical strain on your team.

- Customized Solutions: Tailor the bins to your specific needs. We offer various sizes, configurations, and features to ensure your bins perfectly fit your requirements.

- Cost Savings: Enjoy cost-efficiency with MTCPlast. Our Picking Bins are an investment in long-term savings through enhanced productivity and reduced operational costs

- Exceptional Support: When you choose us, you're choosing more than just a product; you're getting a dedicated partner. Our expert support ensures you get the most out of your investment.