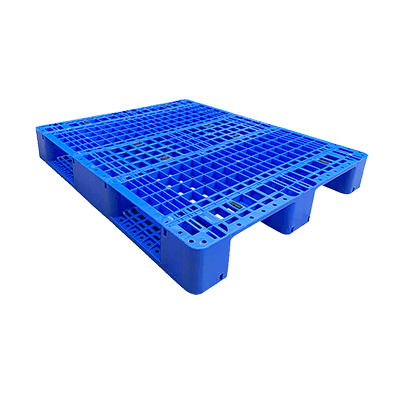

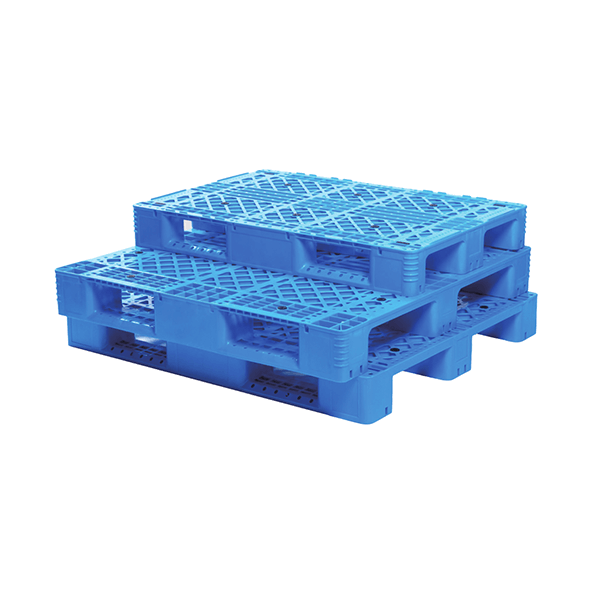

Rackable Plastic Pallets

Engineered to withstand heavy loads and racking systems, our rackable plastic pallets are ideal for warehouse storage. Their reinforced structure and uniform design allow for seamless integration into your racking system, optimizing your inventory management.

Welcome to our comprehensive guide to rackable plastic pallets. In this guide, we will provide you with all the essential information you need to know about rackable plastic pallets, including their identification, benefits, our company advantages, services, applications, FAQs, and more. Whether you’re a business owner, warehouse manager, or logistics professional, this guide will help you make an informed decision when purchasing rackable plastic pallets.

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the download link immediately.

Introduction to Rackable Plastic Pallets

Definition and Purpose of Rackable Plastic Pallets

Rackable plastic pallets are specially designed to offer optimal storage solutions in warehouse racking systems. Their structural integrity and strength allow them to be safely stacked in high racks, optimizing vertical storage space.

Key Features and Characteristics

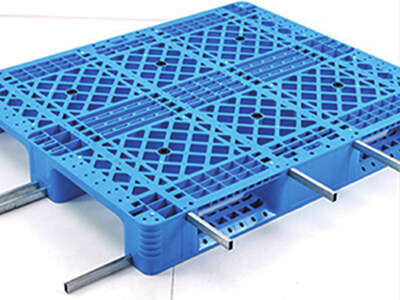

These pallets are typically made from high-quality, durable plastic materials like HDPE (high-density polyethylene) or PP (polypropylene). They are built with reinforced features such as ribbing or steel bars for increased strength and load-bearing capacity. Rackable pallets are engineered to support heavy loads, with weight capacities ranging from 2,000 to 5,000 pounds. They distribute the load evenly to prevent damage to the goods and provide stability during stacking.

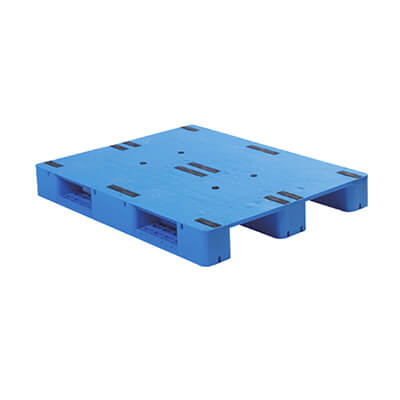

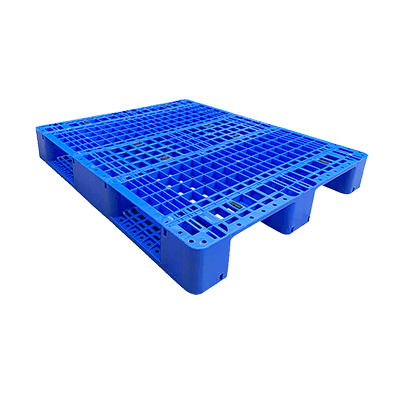

Mtcplast Rackable Plastic Pallets Series

Want to purchase plastic pallets onboard? This ultimate solution guide would help you everything about buying products.

Advantages of Using Rackable Pallets in Storage Environments

Discover the numerous benefits of using rackable plastic pallets, including improved space utilization, reduced product damage, and enhanced efficiency in handling and storing goods.

Maximize Vertical Storage with Racking System Compatibility

Rackable pallets are designed to fit seamlessly into various racking systems. With the ability to stack vertically, rackable plastic pallets allow you to efficiently utilize available storage space, optimizing your warehouse layout.

Improved Warehouse Efficiency and Organization

Experience streamlined material handling processes with our rackable pallets, enhancing overall warehouse efficiency and organization.

Reduced Risk of Product Damage

Rackable plastic pallets provide a smooth and consistent surface, minimizing the risk of product damage during handling and storage.

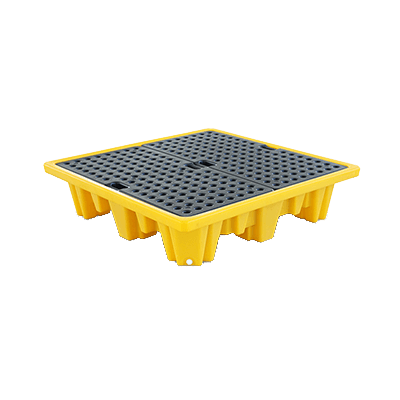

Enhanced Hygiene and Sanitation

Benefit from the hygienic properties of plastic, as our pallets do not absorb moisture or harbor bacteria, making them ideal for industries with stringent hygiene standards.

Cost-Effectiveness and Long-Term Savings

Investing in durable rackable plastic pallets can lead to long-term cost savings due to their extended lifespan and reduced need for frequent replacements.

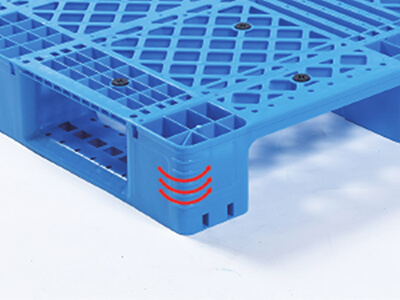

Rounded corner to prevent collisions

The rounded column leg design provides cushioning upon impact and serves as a collision prevention measure during forklift operations, thereby extending the lifespan of the pallet.

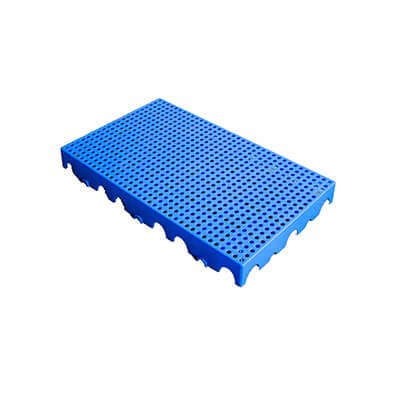

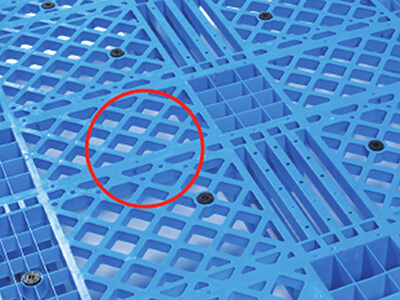

Mesh perforations design

The surface’s perforated design of plastic pallets facilitates water resistance and moisture prevention, ensuring proper ventilation for the bottom of the goods.

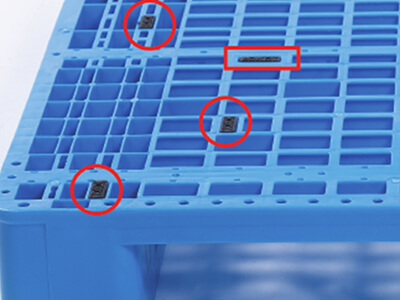

Anti-slip pad design on the surface

The anti-slip pad design on the surface of the pallet provides good friction between the pallet surface and the goods, preventing them from sliding off the pallet.

Design with optional steel tubes

Design with the option to add steel tubes, catering to various load requirements.

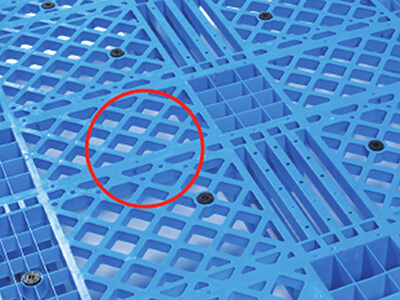

Bottom anti-slip pad design

The bottom anti-slip pad design on the pallet provides friction between the pallet and the floor or shelving, ensuring that the pallet remains stable and does not easily slide or fall off the shelves.

Suitable for various types of shelving and flat ground use.

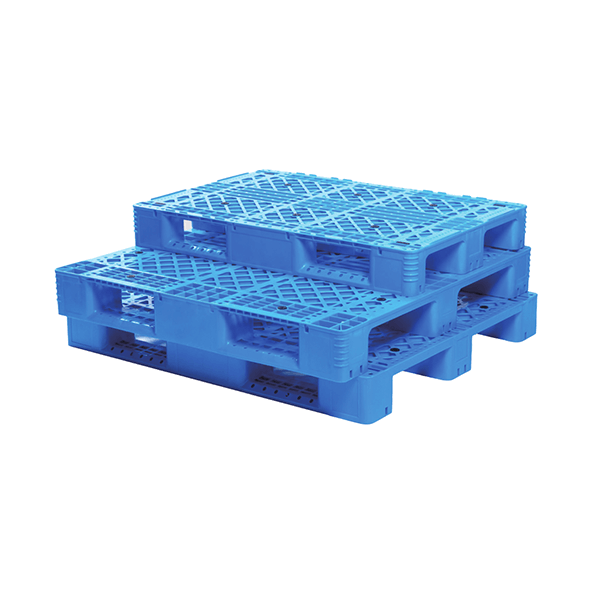

The 3-runner design pallet has a high load-bearing capacity and is convenient for forklift use. It can be used for flat ground handling and is compatible with different types of shelving structures, such as beam-style racks, drive-in racks, and automated warehouses.

Rackable Plastic Pallets Application

Rackable plastic pallets find applications across various industries. Here are some common applications

How to Identifying Rackable Plastic Pallets

Identifying rackable plastic pallets involves examining specific characteristics and features. Here are some key aspects to consider when identifying rackable plastic pallets

Design and Construction

Rackable plastic pallets typically have a sturdy construction with reinforced areas to support heavy loads when placed on racks. Look for additional reinforcements, such as steel bars or ribbing, that provide strength and durability.

Nine-Leg or Three-Runner Design

Rackable plastic pallets often feature a specific design with either nine legs or three runners. The nine-leg design provides enhanced stability and weight distribution, while the three-runner design allows for compatibility with forklifts and racking systems.

Load Capacity

Rackable plastic pallets are designed to withstand higher weight capacities compared to standard pallets. They typically have load capacities 1000kg .

Why Choose Mtcplast.com?

At MTCPLAST, we take pride in offering exceptional rackable plastic pallets and services. Here’s why you should choose us

Extensive Industry Experience

With years of experience in the material handling industry, we have a deep understanding of the specific needs and challenges faced by businesses when it comes to storage and logistics.

High-Quality Products

Our rackable plastic pallets are manufactured using premium-grade materials and advanced production techniques, ensuring exceptional quality and durability.

Customization Options

We offer a wide range of customization options, allowing you to tailor our rackable pallets to meet your exact specifications and branding requirements.

Expert Technical Support

Our team of experts is always available to provide technical support and guidance, helping you choose the right rackable pallets for your unique storage needs.

Competitive Pricing

We offer competitive pricing without compromising on product quality, ensuring you get the best value for your investment.

Timely Delivery

We understand the importance of timely delivery, and our efficient logistics ensure that your rackable plastic pallets reach you when you need them.

By choosing us as your rackable plastic pallet supplier, you can expect top-notch products, personalized solutions, and a reliable partner for all your material handling needs.

Estimate Price of Rackable Plastic Pallets

The estimated price of rackable plastic pallets can vary depending on several factors, such as the size, design, load capacity, customization requirements, and order quantity. It is recommended to contact our sales team or request a quote to get an accurate estimate based on your specific pallet specifications and order details. Our team will be happy to provide you with a competitive pricing proposal tailored to your needs. Below is an outline of costs you will incur:

Sample Product Fee

Pay a minimal amount in case you need a sample plastic pallet. Well, this money is for a single sample, if it is the one that you need. With several samples, you’ll pay a bit more.

30% T/T Fee

You can decide to either pay the full amount or pay 30% of the full payment for the wholesale.

70% Final Fee

Complete your payment within a certain period and receive the products you ordered for.

Shipping Fee

This is the amount of money that you will pay for the transportation of your products from the factory to your doorstep. MTCPLAST offers you the convenience of any kind.

Estimated Manufacturing and Shipping Times

The estimated manufacturing and shipping times of nestable plastic pallets can vary based on several factors, including the order quantity, customization requirements, and current production capacity. Here’s a general overview of the process

Manufacturing Time

The manufacturing time for rackable plastic pallets typically depends on the production volume and complexity of the order. Smaller orders with standard specifications may have a quicker turnaround time, while larger or customized orders may require additional production time. It is best to consult with our sales team to get an accurate estimate based on your specific requirements. Generally it takes 15-25 working days to finish your order if witin 3000pcs

Customs declearance and loading

Once your order is finished and we get the balance of the order, we’ll load them onto vans and wait for them to be decleared by Customs.

International Delivery

After decleared, your plastic pallets will then be shipped to you through international waters. You’ll receive an alert on your mobile device when your order arrives.

Steps to Work with Us

Working with us is a straightforward process designed to ensure a smooth experience for our customers. Here are the steps to work with us:

Contact and Consultation

Reach out to us through our website, email, or phone to initiate the conversation. Our responsive team will be available to answer your inquiries, discuss your requirements, and provide any necessary guidance or clarification. We will gather essential details about your needs, such as pallet specifications, quantities, customization requirements, and desired timelines.

Quotation

Based on the information provided, we will prepare a comprehensive quotation tailored to your specific requirements. The quotation will include details such as pricing, delivery timelines, customization options, and any additional services or support you may require. We strive to offer competitive pricing and transparent information to assist you in making an informed decision.

Order Confirmation

Once you review the quotation and are ready to proceed, confirm your order by accepting the quotation and making the necessary arrangements, such as providing payment details and signing any required documentation. Our team will guide you through this process and address any questions or concerns you may have.

Manufacturing and Customization

Our skilled manufacturing team will begin the production process according to the agreed-upon specifications. If you have requested any customization, such as size variations, color choices, or branding options, our experts will ensure that your pallets are tailored to your specific needs. Throughout the manufacturing process, we maintain stringent quality control measures to ensure the highest standards are met.

Quality Assurance and Inspection

Before shipment, our quality assurance team will thoroughly inspect the finished plastic pallets to ensure they meet our rigorous quality standards. This inspection process includes checking for any defects, verifying dimensions and load capacities, and ensuring compliance with any requested customization.

Shipping and Delivery

Once the quality inspection is completed, we will arrange the shipping and delivery of your plastic pallets. We work with trusted logistics partners to ensure prompt and reliable delivery to your desired location. Shipping times may vary depending on the destination and shipping method chosen. We will provide you with tracking information so you can monitor the progress of your shipment.

After-Sales Support

Our commitment to your satisfaction extends beyond the delivery of your plastic pallets. We offer comprehensive after-sales support to address any post-delivery questions, concerns, or issues that may arise. Our dedicated customer support team is available to assist you with any further inquiries, technical guidance, or ongoing collaboration.

Things You Need to Know

Frequently Asked Questions (FAQs) – Rackable Plastic Pallets: Your Queries Answered

What is the difference between rackable, nestable, and stackable pallets?

Rackable pallets are designed for use in racking systems and can withstand the weight and pressure of being stacked on racks. Nestable pallets are designed to fit together when empty, reducing storage space. Stackable pallets can be safely stacked on top of each other, even without a racking system.

Are rackable plastic pallets suitable for outdoor use?

Yes, rackable plastic pallets are suitable for outdoor use. They are resistant to weather conditions, UV radiation, and moisture, making them ideal for both indoor and outdoor applications.

What is the expected lifespan of rackable plastic pallets?

The lifespan of rackable plastic pallets can vary depending on usage and maintenance. However, with proper care and handling, these pallets can last for many years, providing a long-term return on investment compared to traditional pallets.

Can rackable plastic pallets be used in high-humidity environments?

Yes, rackable plastic pallets are designed to withstand high-humidity environments. They are resistant to moisture absorption, which helps maintain their structural integrity and prevents warping or degradation.

Can rackable plastic pallets be used in automated systems?

Absolutely! Rackable plastic pallets are suitable for use in automated systems such as conveyor belts and forklift operations. Their consistent dimensions and durability make them compatible with various automated handling equipment.

Are rackable plastic pallets compatible with all types of racking systems?

Rackable plastic pallets are designed to be compatible with most common racking systems, including selective, push-back, drive-in, and pallet flow racks. However, it is essential to ensure proper compatibility and check specific weight capacity requirements for your chosen racking system.

How should rackable plastic pallets be cleaned and maintained?

Rackable plastic pallets are easy to clean and maintain. They can be cleaned using common cleaning agents, water, or pressure washing. Regular inspections should be performed to identify any damage or wear, and damaged pallets should be repaired or replaced promptly to ensure their continued performance. requirements.

What are the advantages of plastic pallets over wood pallets?

Plastic pallets offer several advantages over wood pallets. They are more durable, resistant to moisture and pests, and have a consistent weight and size. Plastic pallets are also easier to clean, hygienic, and can be recycled at the end of their life, contributing to sustainability efforts.

How do rackable plastic pallets contribute to space optimization in warehouses?

Rackable plastic pallets are designed to maximize storage space in warehouses. Their stackability allows for efficient vertical storage, freeing up floor space and enabling better organization and inventory management.

Ready to Optimize Your Warehouse Space?

Discover the advantages of MTCPlast’s rackable plastic pallets:

- Space Efficiency: Maximize your warehouse space by securely storing products vertically, reducing clutter, and allowing for organized, efficient storage.

- Durability: Count on our pallets' sturdy construction, minimizing wear and tear, and lowering replacement costs.

- Cost-Effective: Decrease transport and storage expenses with the exceptional load-bearing capacity of our rackable pallets.

- Customization: Tailor pallets to your unique requirements for seamless integration into your operations.

- Eco-Friendly Solutions: Choose sustainable materials, aligning with your environmental goals.

At MTCPlast, we’re committed to your success. Join the ranks of satisfied customers who have transformed their material handling. Contact us to unlock the efficiency and cost savings of rackable plastic pallets.

Enhance your warehouse capabilities with the smart choice for your business today!