Spill Pallets

Ensure safe and compliant storage of hazardous materials with our spill pallets. Designed with containment features, these pallets prevent leaks and spills, protecting both your products and the environment. Ideal for industries with strict safety regulations.

Welcome to the comprehensive product page dedicated to spill pallets – your definitive resource for understanding, selecting, and optimizing the use of these essential tools in liquid containment. Explore the various facets of spill pallets and their pivotal role in preventing environmental hazards and ensuring compliance with safety regulations.

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the download link immediately.

Introduction to Spill Pallets

Definition of Spill Pallets

Spill pallets are specialized containment platforms designed to prevent leaks, spills, and drips from hazardous liquids, chemicals, or materials. These pallets feature raised edges or barriers that capture and contain any spilled liquid, preventing it from spreading and causing environmental contamination. Spill pallets are commonly used in industrial settings, warehouses, and transportation to ensure compliance with safety regulations, protect the environment, and reduce the risks associated with handling hazardous substances. They play a critical role in maintaining workplace safety, preventing pollution, and facilitating the proper management and disposal of spilled liquids.

- The Importance of Spill Containment:Understand why spill pallets are a crucial component in industries dealing with hazardous liquids, preventing costly damage and ensuring compliance with environmental regulations.

- Mitigating Risks:Explore how spill pallets contribute to risk reduction by providing a reliable secondary containment system that safeguards against leaks, spills, and potential harm to employees and the environment.

- Compliance and Responsibility:Learn how the use of spill pallets aligns with industry standards and demonstrates your commitment to responsible liquid handling practices.

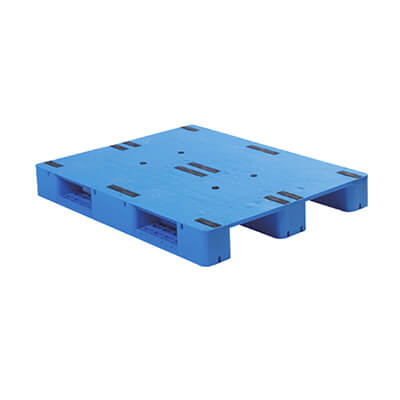

Spill Pallets Product Series

Uncover the manifold advantages that spill pallets bring to industries handling liquids, chemicals, and hazardous materials. From preventing spills and environmental contamination to facilitating easy cleanup, these benefits redefine workplace safety and regulatory compliance.

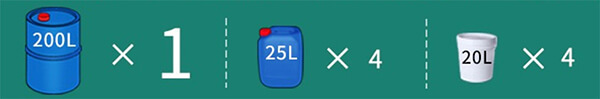

Spill containment pallet 1 drum

Dimension:675*675*150

Dynamic Load:None

Rack Load:500kg

Spill containment capacity:43L/11 us gal

- This pallet is suitable for storing either one 200-liter oil drum, four 25-liter oil drums, or four paint buckets.

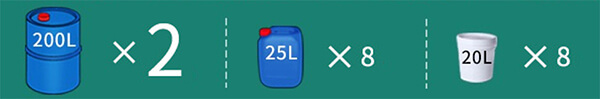

Spill containment pallet 2 drums

Dimension: 1300*690*150

Dynamic Load:600 kg

Rack Load:1200kg

Spill containment capacity:43L/18 us gal

- This pallet is suitable for storing either two 200-liter oil drum, eight 25-liter oil drums, or 8 paint buckets.

- Suitable for motorized forklifts and 550&680 pallet jacks

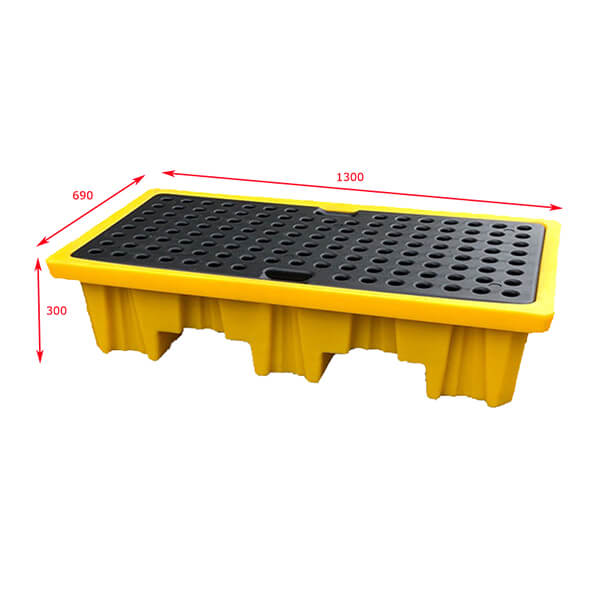

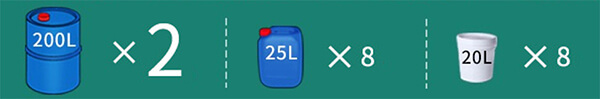

Spill containment pallet 2 drums

Dimension:1300*690*300

Dynamic Load:600 kg

Rack Load:1200kg

Spill containment capacity:150L/42 us gal

- This pallet is suitable for storing either two 200-liter oil drum, eight 25-liter oil drums, or 8 paint buckets.

- Suitable for motorized forklifts and 550&680 pallet jacks

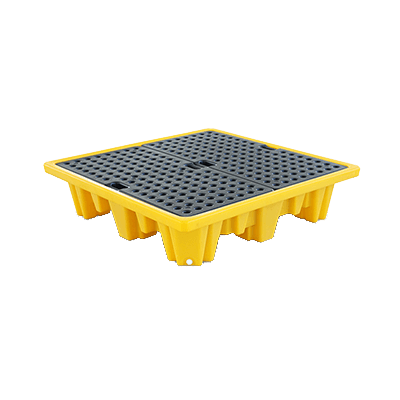

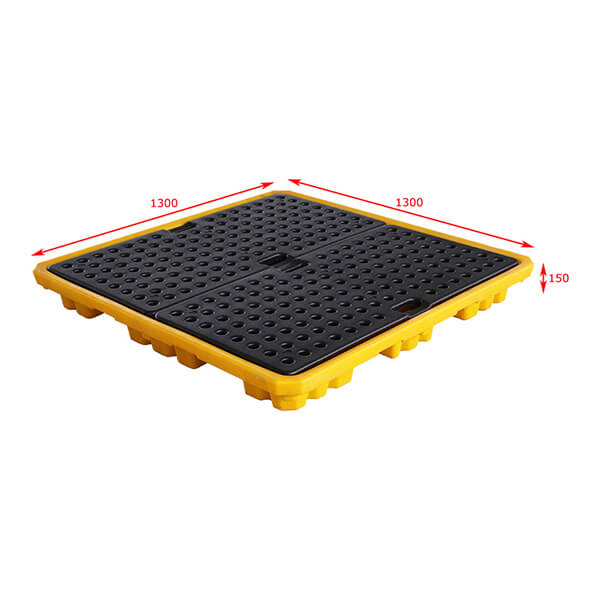

Spill containment pallet 4 drums

Dimension:1300*1300*150

Dynamic Load:1200kg

Rack Load:2600kg

Spill containment capacity:120L/32 us gal

- This pallet is suitable for storing either two 200-liter oil drum, eight 25-liter oil drums, or 8 paint buckets.

- Suitable for motorized forklifts and 680 pallet jacks

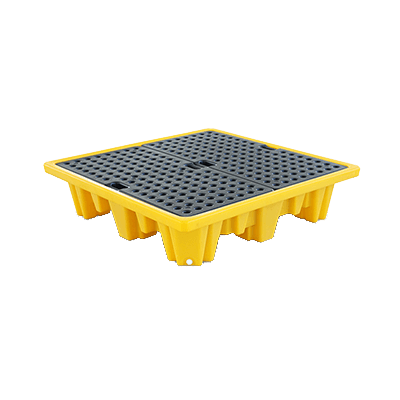

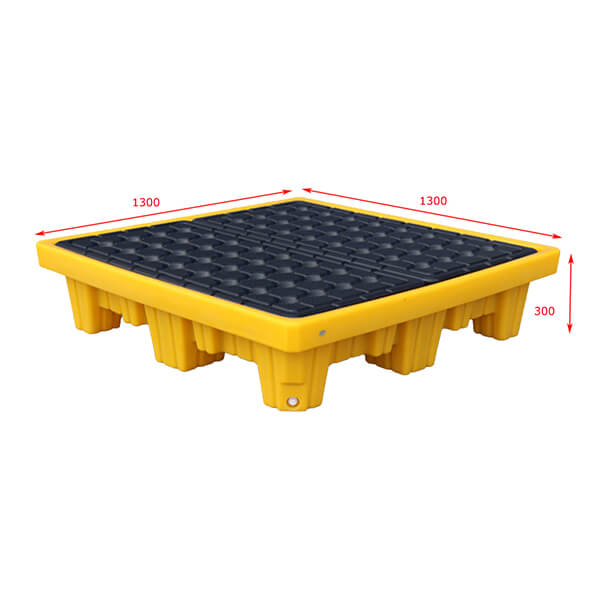

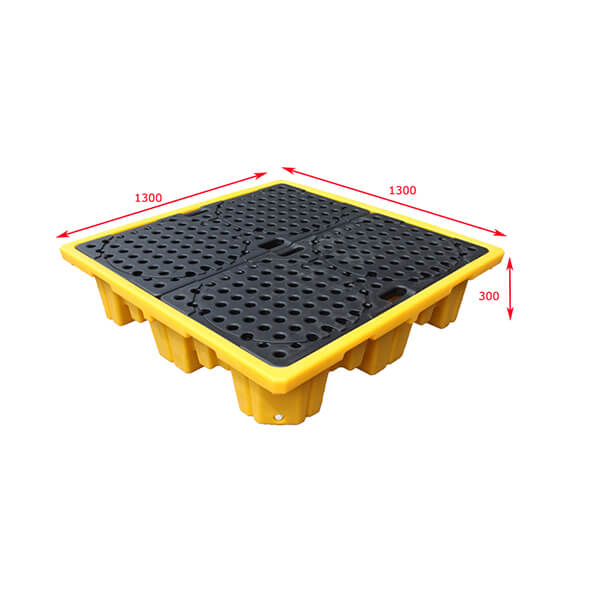

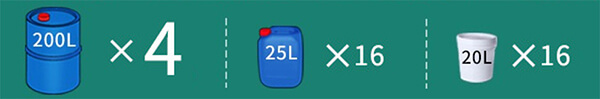

Spill containment pallet 4 drums

Dimension:1300*1300*300

Dynamic Load:1200kg

Rack Load:3000kg

Spill containment capacity:260L/69 us gal

- This pallet is suitable for storing either two 200-liter oil drum, eight 25-liter oil drums, or 8 paint buckets.

- Suitable for motorized forklifts and 550&680 pallet jacks

Spill containment pallet 4 drums

Dimension:1300*1300*300

Dynamic Load:1000kg

Rack Load:2800kg

Spill containment capacity:280L/62 us gal

- This pallet is suitable for storing either two 200-liter oil drum, eight 25-liter oil drums, or 8 paint buckets.

- Suitable for motorized forklifts and 550&680 pallet jacks

Unlocking Safety and Efficiency in Liquid Containment

Key Features and Benefits of Spill Pallets

In this chapter, we delve into the core features and advantages that spill pallets bring to your liquid containment practices. Explore how these specialized platforms redefine workplace safety, prevent environmental damage, and optimize your operations.

Containment Excellence

Spill pallets feature raised edges or barriers that effectively contain liquids in the event of leaks or spills, preventing the spread of hazardous substances and minimizing risks.

Preventing Environmental Hazards

By containing spills, spill pallets contribute to preventing environmental contamination, safeguarding soil, water sources, and the ecosystem from potential harm.

Regulatory Compliance Assurance

Using spill pallets ensures compliance with safety regulations and guidelines for containing hazardous materials. Avoid fines and penalties while demonstrating responsible liquid handling practices.

Simplified Cleanup

Spill pallets facilitate easy cleanup by capturing spilled liquids, making disposal more efficient and reducing cleanup time, effort, and costs.

Customized Solutions

Tailor spill pallets to match your unique requirements. With customization options for size, features, and materials, you can optimize liquid containment in alignment with your operational needs.

Enhancing Workplace Safety

Implementing spill pallets reduces the risk of slips, trips, and falls caused by liquid spills. Promote a safer work environment for your employees while mitigating accidents.

Versatile Applications

Spill pallets are adaptable across various industries and liquid handling scenarios. From manufacturing to transportation, they ensure consistent safety standards.

Long-Term Cost Savings

Spill pallets are adaptable across various industries and liquid handling scenarios. From manufacturing to transportation, they ensure consistent safety standards.

Sustainability Contributions

Select spill pallets made from durable, reusable materials to minimize waste generation and promote environmental sustainability.

Enhanced Non-Slip Design

These spill pallets feature thickened non-slip separators with textured surfaces, significantly boosting the friction between goods and the pallet surface. This ensures worry-free cargo handling without the risk of items slipping off.

Easy Disassembly for Cleaning

Our spill pallets feature advanced rotational molding technology, ensuring a smooth and burr-free surface. Combined with detachable partitions, they are exceptionally easy to disassemble and clean, providing added convenience.

Large Containment Capacity

In the event of a drum leak, all spilled liquids are directed into the spill pallet through the partitions, preventing on-site environmental contamination.

Nut-Style Drain System

The new nut-style drain system simplifies drainage operations compared to older methods. It ensures an environmentally friendly and leak-free solution for handling spills.

Reinforced Ribbed Design

The spill pallets are engineered with reinforced ribs, enhancing their impact resistance and further increasing their load-bearing capacity, providing added peace of mind during use.

Versatility Across Industries

Delve into the diverse applications of spill pallets across various sectors. From manufacturing and chemical processing to storage and transportation, witness how these pallets adapt seamlessly, enhancing the safety and efficiency of liquid containment.

For containment warehouse storage

For Chemical products warehouse storage

For auto repair shops

Tailoring Excellence to Your Agricultural Needs

Customization and Selection Criteria for Harvest Bins

In this chapter, we delve into the realm of customization and guide you through essential selection criteria for choosing the perfect spill pallets that align with your specific liquid containment requirements. Explore how customization options empower you to match the characteristics of your liquids, while informed selection ensures optimal safety and compliance.

Customization Options

Material Selection

Choose spill pallets crafted from materials compatible with the liquids you handle, ensuring optimal resistance to chemical reactions and corrosion.

Capacity and Size Variations

Tailor spill pallets to accommodate various container sizes and liquid volumes, optimizing their effectiveness for different liquid containment scenarios.

Additional Features

Explore options like ramps, grates, and drain plugs that enhance the usability and convenience of spill pallets based on your unique operational needs.

Modular Configurations

Discover spill pallets designed to be stacked or connected, offering flexibility in creating larger containment areas for bulk storage or multiple containers.

Selection Criteria

Compatibility with Liquids

Evaluate the compatibility of the spill pallet material with the liquids or chemicals you handle to prevent unwanted reactions and ensure containment integrity.

Container Size and Quantity

Choose spill pallets that can accommodate the sizes and quantities of containers you use, minimizing the risk of overflow and maximizing efficiency.

Regulatory Compliance

Ensure that selected spill pallets meet industry and regulatory standards, ensuring compliance with spill containment and safety requirements.

Space and Layout

Consider the available space and layout of your facility to determine the appropriate spill pallet dimensions and configurations that fit seamlessly.

Mobility and Accessibility

If needed, select spill pallets with features such as forklift pockets or built-in ramps for easy maneuverability and accessibility.

By customizing your spill pallets to your specific liquid containment needs and applying the right selection criteria, you ensure workplace safety, environmental protection, and regulatory compliance. At [Your Company Name], we understand the importance of tailored solutions and are committed to guiding you toward the perfect spill pallets for your operations.

Environmental Impact

Opt for spill pallets made from sustainable materials that align with your company’s environmental objectives, contributing to responsible liquid containment.

Customization and Selection Criteria for Spill Pallets

Want to purchase plastic pallets onboard? This ultimate solution guide would help you everything about buying products.

Design and Structure

Nestable plastic pallets feature an open deck design with slats or grids that provide ample ventilation and drainage. They may have runners or skids for added stability and load distribution. The design may also incorporate corner reinforcements and anti-slip surfaces for improved safety.

Load Capacity and Dimensions

Nestable plastic pallets come in various sizes and load capacities to accommodate different applications. Common dimensions include 48″ x 40″ and 1200mm x 1000mm, with load capacities ranging from 1,000 to 5,000 pounds (450 to 2,270 kilograms).

Color Coding and Identification

Many manufacturers offer color-coded nestable plastic pallets to facilitate easy identification and sorting. Different colors can represent specific load capacities, industry applications, or company branding.

Your Trusted Ally in Liquid Containment

Partner with Mtcplast for Spill Pallet Solutions

In this final chapter, we invite you to discover why Mtcplast stands as the premier partner for your spill pallet needs. Explore how our commitment to excellence, customizable solutions, and exceptional customer support elevate your liquid containment practices to the highest standards.

Industry-Leading Expertise

Benefit from years of industry expertise as Mtcplast specializes in spill containment solutions. Our team understands the nuances of liquid handling safety, enabling us to provide tailored advice and solutions that optimize your operations.

Customization Beyond Boundaries

Experience a new level of customization with Mtcplast. Our spill pallets can be tailored to match the unique characteristics of your liquids and operational requirements, ensuring seamless integration.

Premium Quality Assurance

At Mtcplast, quality is paramount. Our spill pallets undergo rigorous testing to meet and exceed industry standards, offering reliable and durable solutions for your liquid containment needs.

Holistic Safety Solutions

Beyond spill pallets, discover a comprehensive suite of safety solutions offered by [Your Company Name]. From secondary containment to emergency response products, we provide a one-stop shop for enhancing workplace safety.

Dedicated Customer Support

Experience unparalleled customer support from [Your Company Name]. Our team is ready to assist you in selecting the perfect spill pallets, addressing inquiries, and ensuring a seamless experience throughout.

Sustainability in Focus

Join us in promoting sustainable safety practices. By choosing Mtcplast, you contribute to eco-friendly practices through the use of durable and reusable spill pallets that minimize waste.

Transformative Safety Measures

When you partner with Mtcplast, you’re not just obtaining spill pallets; you’re embarking on a collaborative journey to elevate safety, reduce risks, and achieve optimal compliance.

Choose Mtcplast as your trusted ally in revolutionizing your liquid containment processes with premium spill pallet solutions. Contact us today to explore our range of customizable solutions, receive expert guidance, and elevate your safety standards.

Navigating Safety Solutions for Optimal Liquid Containment

How to Choose the Right Spill Pallets

In this chapter, we guide you through the process of selecting the ideal spill pallets tailored to your liquid containment needs. By understanding key considerations and informed decision-making, you can elevate workplace safety, prevent environmental hazards, and ensure regulatory compliance.

Identify Liquid Compatibility

Evaluate the types of liquids or chemicals you handle. Select spill pallets made from materials compatible with your specific substances to ensure safe containment and prevent chemical reactions.

Assess Container Sizes and Quantities

Consider the sizes and quantities of containers you use. Choose spill pallets that accommodate your containers comfortably, preventing overflows and ensuring efficient containment.

Regulatory Compliance

Ensure the spill pallets you choose adhere to industry and regulatory standards. This guarantees compliance with safety and containment regulations, preventing fines and penalties.

Space and Layout Considerations

Evaluate the available space and layout of your facility. Opt for spill pallets that fit seamlessly into your workspace while allowing easy access for loading and unloading.

Accessibility and Mobility

If necessary, select spill pallets with features such as built-in ramps or forklift pockets. This ensures easy maneuverability and accessibility, especially when handling heavy containers.

Durability and Maintenance

Consider the durability of spill pallets and their resistance to wear, corrosion, and chemical exposure. Opt for spill pallets that require minimal maintenance while providing long-lasting performance.

Customization Options

Explore spill pallet customization options, such as adding ramps, drain plugs, or other features that enhance functionality and cater to your specific needs.

Steps to Work with Us

Working with us is a straightforward process designed to ensure a smooth experience for our customers. Here are the steps to work with us:

Contact and Consultation

Reach out to us through our website, email, or phone to initiate the conversation. Our responsive team will be available to answer your inquiries, discuss your requirements, and provide any necessary guidance or clarification. We will gather essential details about your needs, such as pallet specifications, quantities, customization requirements, and desired timelines.

Quotation

Based on the information provided, we will prepare a comprehensive quotation tailored to your specific requirements. The quotation will include details such as pricing, delivery timelines, customization options, and any additional services or support you may require. We strive to offer competitive pricing and transparent information to assist you in making an informed decision.

Order Confirmation

Once you review the quotation and are ready to proceed, confirm your order by accepting the quotation and making the necessary arrangements, such as providing payment details and signing any required documentation. Our team will guide you through this process and address any questions or concerns you may have.

Manufacturing and Customization

Our skilled manufacturing team will begin the production process according to the agreed-upon specifications. If you have requested any customization, such as size variations, color choices, or branding options, our experts will ensure that your pallets are tailored to your specific needs. Throughout the manufacturing process, we maintain stringent quality control measures to ensure the highest standards are met.

Quality Assurance and Inspection

Before shipment, our quality assurance team will thoroughly inspect the finished plastic pallets to ensure they meet our rigorous quality standards. This inspection process includes checking for any defects, verifying dimensions and load capacities, and ensuring compliance with any requested customization.

Shipping and Delivery

Once the quality inspection is completed, we will arrange the shipping and delivery of your plastic pallets. We work with trusted logistics partners to ensure prompt and reliable delivery to your desired location. Shipping times may vary depending on the destination and shipping method chosen. We will provide you with tracking information so you can monitor the progress of your shipment.

After-Sales Support

Our commitment to your satisfaction extends beyond the delivery of your plastic pallets. We offer comprehensive after-sales support to address any post-delivery questions, concerns, or issues that may arise. Our dedicated customer support team is available to assist you with any further inquiries, technical guidance, or ongoing collaboration.

Answers to Your Common Questions

FAQs: Spill Pallets Demystified

In this chapter, we address frequently asked questions about spill pallets, providing insights into their usage, benefits, and considerations. Gain a deeper understanding of how spill pallets contribute to safety, environmental protection, and regulatory compliance.

What are spill pallets used for?

Spill pallets are used to contain leaks and spills of hazardous liquids, preventing environmental contamination, workplace accidents, and ensuring compliance with safety regulations.

Are spill pallets customizable?

Yes, spill pallets can be customized to match the characteristics of the liquids you handle, as well as your operational requirements, ensuring optimal containment solutions.

How do spill pallets prevent pollution?

Spill pallets capture and contain spilled liquids, preventing them from spreading and reaching soil, water sources, or the environment, thereby minimizing the risk of pollution.

Are spill pallets required by regulations?

Spill pallets are often required by regulations to ensure safe liquid handling and containment. Adhering to these regulations helps prevent fines, penalties, and legal liabilities.

What materials are spill pallets made from?

Spill pallets are typically made from durable materials like polyethylene or steel. The material choice depends on the types of liquids you handle and their compatibility.

Can spill pallets be reused?

Yes, many spill pallets are designed for reuse. Opting for reusable spill pallets contributes to sustainability by minimizing waste generation.

How do I choose the right spill pallets for my needs?

Select spill pallets based on factors such as liquid compatibility, container sizes, regulatory compliance, and space constraints. Consulting with experts can help you make an informed decision.

Can spill pallets be used for transportation?

Yes, spill pallets can be used during transportation to contain spills in case of accidents or leaks, ensuring safety and compliance throughout the journey.

By addressing these common questions, we aim to provide clarity and insights into the world of spill pallets. If you have additional questions or require further information, feel free to reach out to Mtcplast.

Your Partner in Safety and Compliance

Ready to Safeguard Your Workplace and Environment?

Take the first step towards ensuring safety and compliance with MTCPlast’s spill pallets:

- Environmental Protection: Shield your surroundings from hazardous spills. Our spill pallets are designed to capture and contain potential leaks, preserving the integrity of your workplace and the environment.

- Regulatory Compliance: Stay ahead of regulations and avoid costly fines. Our spill pallets are built to meet stringent safety standards and keep you compliant with spill containment regulations.

- Simplified Maintenance: Minimize downtime and maintenance costs. With our spill pallets, cleaning and decontamination are a breeze, allowing you to focus on your core operations.

- Custom Solutions: Tailor spill pallets to your specific needs, ensuring a seamless fit into your workplace.

- Peace of Mind: Rest easy, knowing you have a reliable solution to handle spills effectively and protect your investments.

By choosing MTCPlast’s spill pallets, you’re investing in safety, compliance, and peace of mind. Don’t wait until a spill happens; act now to prevent incidents and safeguard your environment. [Contact us](link to contact page) to explore how spill pallets can benefit your workplace.

Protect your environment, your business, and your peace of mind with MTCPlast’s top-quality spill pallets. Get ahead of spills and compliance issues today!